What does a Aircraft Inspector do?

An Aircraft Inspector plays a crucial role in ensuring the safety and airworthiness of aircraft. This professional inspects aircraft to check for any damage, defects, or compliance with regulations. They conduct thorough visual and mechanical inspections to identify potential hazards. Each inspection includes examining the aircraft’s structure, systems, and components. Inspectors also review maintenance logs and records to ensure all work adheres to standards. Attention to detail is key in this role, as even small issues can affect flight safety.

The Aircraft Inspector works closely with maintenance teams and pilots to schedule inspections and repairs. They often use specialized tools and equipment to perform their duties. This role requires a solid understanding of aircraft mechanics and safety regulations. Inspectors communicate findings clearly and provide recommendations for necessary repairs or modifications. They must stay updated with the latest aviation standards and technologies. By performing these inspections, Aircraft Inspectors help to ensure that all aircraft remain safe for operation.

How to become a Aircraft Inspector?

Starting a career as an Aircraft Inspector involves several key steps. This role is crucial for ensuring that all aircraft meet safety standards. Employers look for individuals who are detail-oriented and can follow strict guidelines.

Following these steps can help pave the way to a successful career as an Aircraft Inspector. Employers value candidates who are committed and thorough in their approach.

- Get the right education: Obtain a high school diploma or GED. Some employers may prefer a degree in aviation or a related field.

- Acquire necessary certifications: Gain FAA certification. This often includes completing an approved training program.

- Gain experience: Work in an entry-level position within the aviation industry. Experience in aircraft maintenance or a related field can be very helpful.

- Develop technical skills: Learn to use tools and equipment used in aircraft inspections. Familiarity with aviation regulations is also essential.

- Apply for jobs: Look for job openings at airlines, repair stations, or government agencies. A strong resume and relevant experience will make the application stand out.

How long does it take to become a Aircraft Inspector?

Learning how to become an Aircraft Inspector can take time. The journey starts with education and training. First, an individual needs a high school diploma or equivalent. Next, they should complete a technical program or vocational school. These programs teach the skills needed for the job. They cover topics like aircraft structures and systems.

After formal training, candidates gain hands-on experience. They often work under a certified inspector. This step allows them to apply what they learned in real situations. They must also pass a written exam. This exam tests their knowledge of aviation safety and regulations. Completing the required training and passing the exam leads to certification. This certification makes the individual a fully qualified Aircraft Inspector.

Aircraft Inspector Job Description Sample

We are seeking a highly detail-oriented and knowledgeable Aircraft Inspector to join our team. The ideal candidate will be responsible for conducting thorough inspections and evaluations of aircraft to ensure compliance with all regulatory requirements and safety standards. This role requires a strong understanding of aircraft structures, systems, and maintenance procedures.

Responsibilities:

- Perform routine and non-routine inspections of aircraft to ensure compliance with FAA regulations and company policies.

- Conduct inspections on new and existing aircraft, including structural, electrical, and mechanical systems.

- Identify and document any discrepancies, defects, or areas requiring maintenance or repair.

- Prepare detailed inspection reports and maintain accurate records of all inspections performed.

- Coordinate with maintenance teams to ensure that identified issues are addressed promptly and effectively.

Qualifications

- Associate’s or Bachelor’s degree in Aviation, Aerospace, or a related field.

- Certification as an Aviation Maintenance Technician (AMT) or Aircraft Structures and Powerplant (A&P) mechanic preferred.

- Minimum of 2 years of experience as an Aircraft Inspector or in a related role within the aviation industry.

- Strong knowledge of aircraft systems, structures, and maintenance procedures.

- Exceptional attention to detail and ability to identify potential issues with high accuracy.

Is becoming a Aircraft Inspector a good career path?

Aircraft Inspectors play a vital role in ensuring air travel safety. They check aircraft to make sure they are in good working order. Inspectors must follow strict guidelines and use detailed knowledge of aircraft systems. Each inspection can take several hours, requiring sharp focus and attention to detail. Working in this role can be both rewarding and challenging.

This job offers many benefits. Aircraft Inspectors enjoy good job security. The demand for air travel means there is always a need for safe aircraft. Inspectors can find work with airlines, maintenance companies, or government agencies. Many inspectors have steady schedules and good pay. Opportunities for travel can be a plus, as inspectors often move between different locations. Being part of a team that ensures flight safety provides a strong sense of purpose. However, there are some downsides to consider. Inspectors face long hours and may work weekends or holidays. The job can be physically demanding, requiring standing for long periods. Travel can also lead to being away from home for extended periods. Some inspectors might find the job stressful due to the high stakes of ensuring safety.

Here are some pros and cons to consider if you are thinking about becoming an Aircraft Inspector:

- Pros:

- Steady job demand

- Good pay and job security

- Variety of employment options

- Sense of purpose in ensuring safety

- Cons:

- Long hours and possible travel

- Physical demands of the job

- Potential for high-stress situations

What is the job outlook for a Aircraft Inspector?

Job seekers interested in becoming an Aircraft Inspector can look forward to a stable and growing field. The Bureau of Labor Statistics (BLS) reports an average of 2400 job positions available each year. This means steady opportunities for those entering the profession. The outlook for growth is also positive, with a projected percent change in job openings of 2.7% from 2022 to 2032. This indicates a relatively healthy growth rate, providing hopeful prospects for those who seek employment in this field.

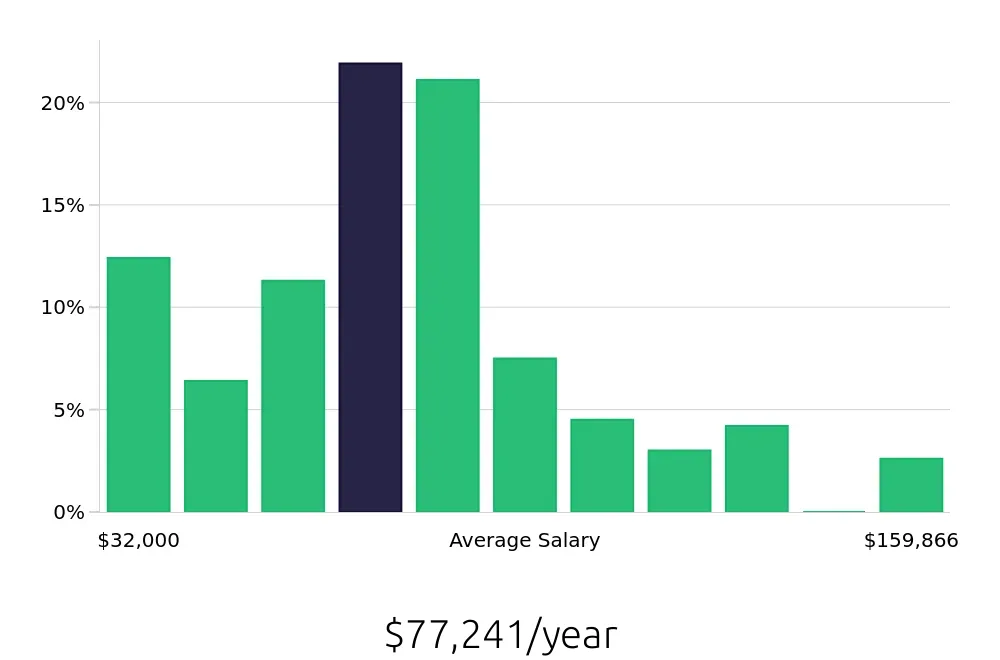

Aircraft Inspectors earn a strong income, making this career attractive to many job seekers. According to the BLS, the average national annual compensation for Aircraft Inspectors stands at $83,920. This competitive salary reflects the high level of skill and responsibility required for the job. In addition to the annual figure, the average national hourly compensation is $40.35. This hourly rate underscores the value placed on the expertise and diligence of Aircraft Inspectors in ensuring aviation safety and compliance.

With both the job outlook and compensation figures promising, the career of an Aircraft Inspector offers a blend of stability and opportunity. Those entering this field can expect a steady number of job positions, a positive growth trend, and a competitive salary. The data from the BLS presents a clear picture of a rewarding career choice for those with the right qualifications and dedication to this essential role.

Currently 20 Aircraft Inspector job openings, nationwide.

Continue to Salaries for Aircraft Inspector