What does a Aircraft Structure Mechanic do?

An Aircraft Structure Mechanic specializes in maintaining and repairing the structural components of aircraft. This includes the airframe, skin, and any metal or composite materials used in construction. Mechanics in this role ensure that the aircraft's structure remains safe and efficient. They inspect parts for wear and damage, perform repairs, and conduct routine maintenance checks. This position requires a strong attention to detail and a solid understanding of mechanical and aerospace principles.

Aircraft Structure Mechanics work closely with other aviation professionals to ensure that aircraft are ready for flight. They use tools and technology to diagnose issues and complete repairs accurately. This role is critical in the aviation industry as it helps keep aircraft safe and operational. Mechanics must stay updated with the latest technology and safety standards to perform their duties effectively. This job offers opportunities for growth and specialization in areas such as composites and advanced materials.

How to become a Aircraft Structure Mechanic?

Becoming an Aircraft Structure Mechanic can lead to a rewarding career. This profession requires technical skills and a keen attention to detail. With the right steps, anyone can enter this exciting field. Follow these steps to start your journey as an Aircraft Structure Mechanic.

The process involves education, certification, and gaining experience. Each step is crucial for success. Here are the key steps to take:

- Complete high school education or equivalent.

- Earn an associate degree in aircraft maintenance or a related field.

- Complete an apprenticeship under a licensed mechanic.

- Obtain the required certifications, such as the FAA Airframe and Powerplant certificates.

- Gain experience through working with a certified aircraft maintenance company.

Each of these steps builds the skills needed for this job. Start by ensuring you have a solid educational foundation. This includes a high school diploma or GED. An associate degree in aircraft maintenance provides the necessary technical knowledge. It covers subjects like aerodynamics, materials science, and mechanical systems.

Next, hands-on experience is key. Complete an apprenticeship with a licensed mechanic. This practical training is essential for learning the skills needed on the job. Once you have completed your training, obtain the necessary certifications. The FAA Airframe and Powerplant certificates are required to work as an Aircraft Structure Mechanic. Finally, gain experience by working with a certified aircraft maintenance company. This step helps to build your resume and prepare for a successful career.

How long does it take to become a Aircraft Structure Mechanic?

Starting a career as an Aircraft Structure Mechanic can lead to a rewarding job with many opportunities. This profession requires special training and education. Most programs take about two to four years to complete.

A typical path involves enrolling in a technical or vocational school program. These programs provide hands-on training and classroom education. Some also offer internships or apprenticeships. Completing a program usually involves about 1,000 to 2,000 hours of study. After finishing a training program, gaining on-the-job experience helps build skills and knowledge. Many mechanics also get certified by passing exams from organizations like the FAA.

An aircraft structure mechanic works on many types of aircraft. They inspect, repair, and maintain the structure of the plane. This includes the fuselage, wings, and landing gear. Their job is vital for ensuring the safety and performance of aircraft. With dedication and the right training, a career in this field offers stability and growth.

Aircraft Structure Mechanic Job Description Sample

The Aircraft Structure Mechanic is responsible for the maintenance, repair, and overhaul of aircraft structures. This role involves inspecting, servicing, and repairing aircraft components to ensure airworthiness and compliance with safety regulations.

Responsibilities:

- Perform routine inspections and maintenance on aircraft structures.

- Diagnose and repair structural issues, including damage to airframes, skin, and components.

- Conduct non-destructive testing and inspections to ensure structural integrity.

- Replace or repair aircraft parts such as frames, skin, and fasteners.

- Use hand and power tools to perform repairs and modifications.

Qualifications

- High school diploma or equivalent; vocational training in aircraft maintenance is preferred.

- FAA Aircraft Maintenance Technician (AMT) certification or equivalent.

- Experience in aircraft structural repair and maintenance.

- Strong understanding of aircraft systems and components.

- Excellent problem-solving skills and attention to detail.

Is becoming a Aircraft Structure Mechanic a good career path?

Aircraft Structure Mechanics play a key role in maintaining and repairing the physical structure of airplanes and helicopters. This career offers hands-on work with advanced tools and technologies. Mechanics inspect, replace, and repair parts to ensure aircraft safety. They often work with a team, requiring both individual skills and teamwork.

Choosing this career has many benefits and some challenges. On the positive side, Aircraft Structure Mechanics can work in various settings, including airports, military bases, and private companies. They often enjoy a stable job market with good pay and benefits. The role provides opportunities for travel and working with cutting-edge technology. However, the job can be physically demanding and requires working in tight spaces. Mechanics must stay updated with the latest aviation technology, which means continuous learning. Some positions may also require working long hours, including nights and weekends.

When considering this career, it's important to weigh these factors carefully.

- Pros:

- Stable job market

- Good pay and benefits

- Opportunities for travel

- Hands-on work with advanced tools

- Cons:

- Physically demanding work

- Continuous learning required

- Potential for long hours

What is the job outlook for a Aircraft Structure Mechanic?

Aircraft Structure Mechanics enjoy a promising job outlook, with an average of 10,900 job positions available each year, according to the Bureau of Labor Statistics (BLS). This steady demand offers numerous opportunities for qualified professionals. The job market for Aircraft Structure Mechanics is expected to grow by 4.3% from 2022 to 2032, which is a positive sign for those considering this career path. This growth rate suggests a stable and growing demand for skilled mechanics in the aviation industry.

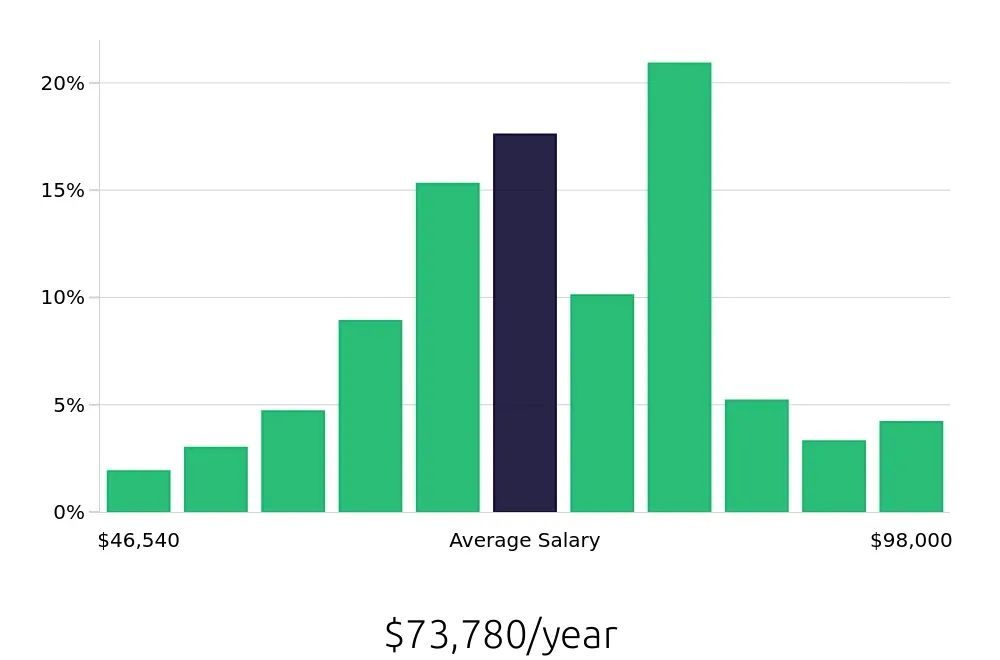

Compensation for Aircraft Structure Mechanics is competitive, with an average national annual salary of $76,260, as reported by the BLS. On an hourly basis, the average compensation stands at $36.66. These figures reflect the value placed on the expertise required to maintain and repair aircraft structures. The steady income and benefits make this a rewarding career choice for those with the right skills and qualifications. Mechanics can also expect to earn more with experience and specialization in certain aircraft types or maintenance techniques.

Job seekers interested in becoming Aircraft Structure Mechanics can look forward to a career with good prospects. The combination of a strong job outlook, competitive salaries, and the chance to work in a dynamic industry makes this career path appealing. With ongoing advancements in aviation technology, the demand for skilled mechanics is likely to remain robust, offering long-term stability and growth potential.

Currently 23 Aircraft Structure Mechanic job openings, nationwide.

Continue to Salaries for Aircraft Structure Mechanic