What does a Blaster do?

A Blaster specializes in using high-pressure water or steam to clean surfaces. They remove dirt, grime, and old paint from various materials. This role requires attention to detail to ensure surfaces are clean and ready for new coatings or decorations. Blasters use specialized equipment to operate safely and efficiently.

Typical tasks for a Blaster include preparing surfaces for painting, inspecting surfaces for damage, and operating power washers or sandblasters. They work outdoors and sometimes indoors. Blasters must follow safety guidelines to protect themselves and others from injury. This job is physically demanding and requires good problem-solving skills. A Blaster must work well under pressure and follow precise instructions to complete tasks correctly.

How to become a Blaster?

Becoming a blaster can open doors to exciting opportunities in the construction and demolition industries. This role involves removing old coatings from surfaces using compressed air or sand. Follow these steps to start a career as a blaster.

First, consider the qualifications needed. A high school diploma or GED is usually required. Technical training or an apprenticeship can provide necessary skills. Look for programs in vocational schools or community colleges that offer courses in surface preparation or industrial cleaning. This training can include classes on safety procedures, equipment operation, and the use of different blasting materials.

- Get trained: Enroll in a vocational or community college program.

- Learn safety: Understand and follow safety protocols to prevent accidents.

- Gain experience: Work under a professional to build skills and confidence.

- Obtain certification: Get certified to enhance job prospects and credibility.

- Find employment: Look for job openings in construction and demolition companies.

Once trained, the next step is to learn about safety. Understand the risks of blasting and the proper use of personal protective equipment (PPE). This knowledge is crucial for a safe working environment. Gaining experience by working with an experienced blaster can help build the practical skills needed for the job. Certification from recognized organizations can set a new blaster apart in the job market. Finally, search for job openings in construction and demolition companies. Networking and attending job fairs can also lead to job opportunities.

How long does it take to become a Blaster?

Interest in becoming a Blaster leads many to wonder about the time it takes to enter this exciting field. The journey to becoming a Blaster involves several steps, each of which requires dedication and time. First, one must complete an education in a relevant field, such as engineering or chemical technology. This foundational education generally takes about four years to complete.

Following the completion of a bachelor’s degree, gaining experience in the industry is crucial. Most professionals recommend at least two to three years of hands-on experience working under supervision. This period allows for mastering the technical skills needed for the job, such as understanding safety protocols and operating specialized equipment. By this stage, many Blasters have gained the necessary skills to work independently, although ongoing learning and development continue throughout one's career.

Blaster Job Description Sample

We are seeking a skilled and safety-conscious Blaster to join our team. The Blaster will be responsible for executing blasting operations in various settings, ensuring compliance with safety regulations and achieving project goals.

Responsibilities:

- Perform blasting operations in accordance with project specifications and safety standards.

- Prepare surfaces for blasting by cleaning, masking, and setting up equipment.

- Operate and maintain blasting equipment, including air compressors, nozzles, and blast media.

- Monitor blast progress and make adjustments to achieve desired results.

- Conduct post-blast inspections to ensure quality and compliance with project requirements.

Qualifications

- Proven experience as a Blaster or similar role in a construction or industrial setting.

- In-depth knowledge of blasting techniques, equipment, and safety procedures.

- Strong understanding of surface preparation methods and materials.

- Proficient in operating and maintaining blasting equipment and tools.

- Ability to read and interpret project specifications and blueprints.

Is becoming a Blaster a good career path?

Working as a blaster involves cleaning surfaces using high-pressure water. This job can happen in many industries, like construction, manufacturing, and maintenance. Blasters often use specialized equipment to remove paint, rust, and other materials from surfaces. This work helps prepare surfaces for painting or other treatments. It can be a good career for someone who likes working outdoors and being physically active.

Becoming a blaster has its advantages and disadvantages. Here are some things to think about. First, blasters often enjoy working outside. They can see different job sites every day. This job also uses physical skills. It can be good for those who enjoy exercise and hands-on work. Another benefit is that it can lead to steady work in many different fields. However, there are downsides, too. The work can be physically demanding and may lead to health issues over time. Blasters also need to follow safety rules carefully to avoid accidents.

Here are some pros and cons of working as a blaster.

- Pros:

- Opportunity to work outside.

- Variety in job sites and tasks.

- Physical work can be fulfilling for some.

- Steady demand in various industries.

- Cons:

- Physically demanding work can lead to health issues.

- Need for strict safety measures to avoid accidents.

- Possible exposure to harsh weather conditions.

What is the job outlook for a Blaster?

For job seekers looking into a career as a Blaster, the job outlook is promising. The Bureau of Labor Statistics (BLS) reports an average of 400 job positions available each year. This consistent demand offers stable opportunities for those seeking a career in this field.

The BLS also shows a projected job openings percent change of 1.1% from 2022 to 2032. This modest increase suggests a steady demand for skilled Blasters in the coming years. Job seekers can expect a relatively stable environment with growing opportunities in this sector.

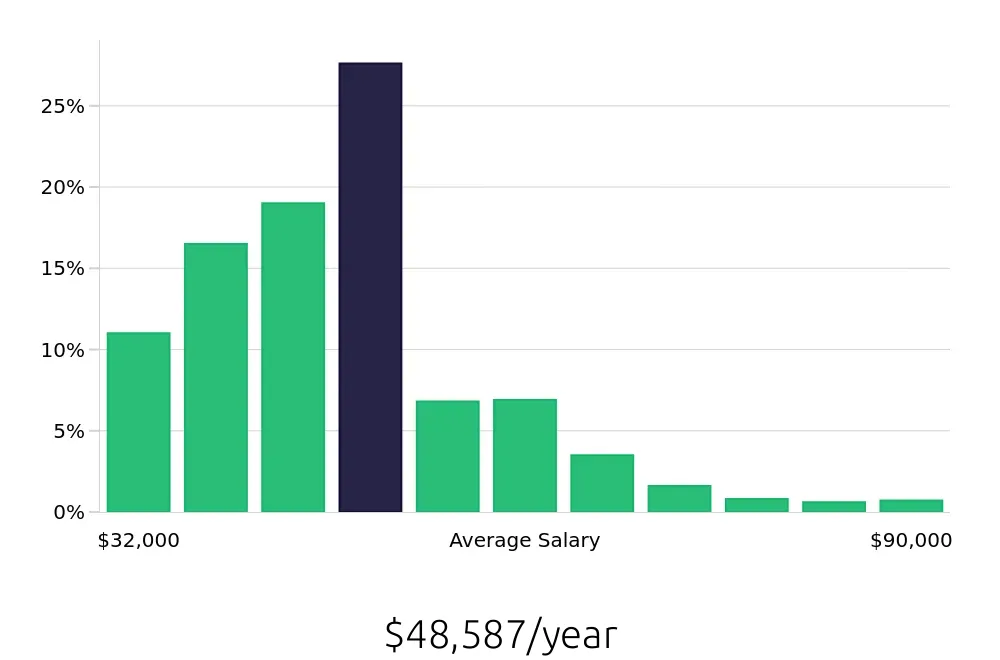

Earnings in this field are competitive, with an average national annual compensation of $65,600. On an hourly basis, Blasters earn an average of $31.54 per hour. This data from the BLS indicates a rewarding career with good financial prospects for those who enter and excel in this profession.

Currently 56 Blaster job openings, nationwide.

Continue to Salaries for Blaster