What does a Certified Welding Inspector do?

A Certified Welding Inspector (CWI) plays a crucial role in ensuring the safety and quality of welds in various industries. This professional examines welds to ensure they meet the required specifications and standards. A CWI uses their knowledge to assess the welding process, materials used, and the final product. They conduct visual inspections and may use advanced tools to ensure welds are strong and reliable.

The CWI also writes reports detailing their findings. They provide detailed feedback and recommendations to improve the welding process. This role requires strong attention to detail and a deep understanding of welding standards and practices. The inspector works closely with welding engineers and other professionals to maintain high-quality standards. A CWI helps prevent costly errors and ensures the integrity of the final product, making them vital in many industries.

How to become a Certified Welding Inspector?

Becoming a Certified Welding Inspector is an excellent career choice for those interested in ensuring the safety and quality of welds. This certification is highly respected in the welding industry. It requires meeting specific educational and experience criteria. Follow these steps to achieve your goal.

Start with formal education. Obtain a high school diploma or GED. Attend a technical school or college to study welding. Courses in metallurgy, blueprint reading, and welding processes are valuable. Many community colleges offer relevant programs.

- Gain practical experience. Work as a welder or welding technician. Aim for at least two years in the field. Experience helps you understand welding techniques and quality standards.

- Pass a written exam. Study for the Certified Welding Inspector exam. Use study guides and practice tests. The exam covers topics like welding codes, standards, and inspection techniques.

- Join a professional organization. Become a member of a group like the American Welding Society (AWS). These organizations offer resources and networking opportunities. They can also provide exam preparation materials.

- Apply for certification. Submit your application to the AWS or another certifying body. Include proof of education, experience, and exam results. Pay the required fees.

- Maintain your certification. Continue learning and working. Take continuing education courses. Stay updated with industry standards. Renew your certification as needed.

Following these steps helps you become a Certified Welding Inspector. This certification opens doors to better job opportunities and higher pay. It shows employers your commitment to quality and safety in welding.

How long does it take to become a Certified Welding Inspector?

The journey to becoming a Certified Welding Inspector involves several steps. First, a person needs to gain experience as a welder. This can take 2 to 4 years. Experience includes working on welding projects and learning the different types of welds.

Next, the individual must complete the required training. This training covers welding codes and standards. A person can take classes at a technical school or through a professional organization. Training can last from a few weeks to several months. After finishing training, the person needs to pass a certification exam. This exam tests knowledge of welding and inspection. Passing the exam leads to certification as a Welding Inspector.

Certified Welding Inspector Job Description Sample

We are seeking a meticulous and experienced Certified Welding Inspector to join our team. The ideal candidate will be responsible for ensuring the quality and safety of welding processes and procedures, in compliance with industry standards and regulatory requirements.

Responsibilities:

- Perform and document inspection of welding processes and procedures in accordance with applicable codes, standards, and specifications.

- Conduct non-destructive testing (NDT) and visual inspections to ensure the quality and integrity of welds.

- Review and interpret welding procedures, process specifications, and inspection plans.

- Ensure compliance with industry standards such as AWS, ASME, API, and other relevant codes and regulations.

- Maintain accurate and detailed inspection records and reports.

Qualifications

- Certified Welding Inspector (CWI) certification from a recognized body (e.g., AWS, ASNT, or similar).

- Minimum of 3-5 years of experience in welding inspection in an industrial or construction environment.

- Proficiency in non-destructive testing (NDT) methods such as UT, MT, PT, RT, and VT.

- Strong knowledge of welding codes and standards such as AWS D1.1, AWS D17.1, ASME B31.1, and API 1104.

- Attention to detail and ability to work in a fast-paced environment.

Is becoming a Certified Welding Inspector a good career path?

A Certified Welding Inspector plays a critical role in ensuring that welded products meet safety and quality standards. This role combines technical knowledge with meticulous attention to detail. Inspectors use specialized tools and training to check welds, both in manufacturing and construction settings. They often work with engineers and welders to identify issues early in the process, helping to prevent costly mistakes.

The career path for a Certified Welding Inspector can lead to a variety of job opportunities. Inspectors can find work in industries such as construction, manufacturing, and engineering. They can also become consultants, helping companies maintain compliance with welding standards. Continuous education and additional certifications can open doors to higher-paying positions and more complex projects.

Being a Certified Welding Inspector has several advantages. First, the demand for skilled inspectors remains steady as welding continues to be crucial in many industries. The job often offers good pay and benefits, especially for those with certifications and experience. Inspectors also enjoy a variety of work environments, from factories to construction sites. However, there are challenges to consider. Inspectors must pay close attention to detail, which can be stressful. They also face physical demands, such as working in cramped spaces or standing for long periods.

Here are some pros and cons to think about:

- Pros:

- Steady job demand across various industries.

- Good pay and benefits.

- Variety of work environments.

- Cons:

- Requires close attention to detail, which can be stressful.

- Physical demands, such as working in tight spaces or standing for long hours.

- Potential exposure to hazardous materials.

What is the job outlook for a Certified Welding Inspector?

The job outlook for Certified Welding Inspectors (CWI) remains promising for those seeking career opportunities in this field. With an average of 64,300 positions available annually, as reported by the BLS, CWIs are in steady demand across various industries.

Looking ahead, the job openings for CWIs are expected to decrease by 3.9% from 2022 to 2032. Despite this projected decline, the role of CWIs remains crucial for ensuring the quality and safety of welded structures. CWIs must hold the appropriate certification and pass a rigorous examination, which underscores the value of their expertise.

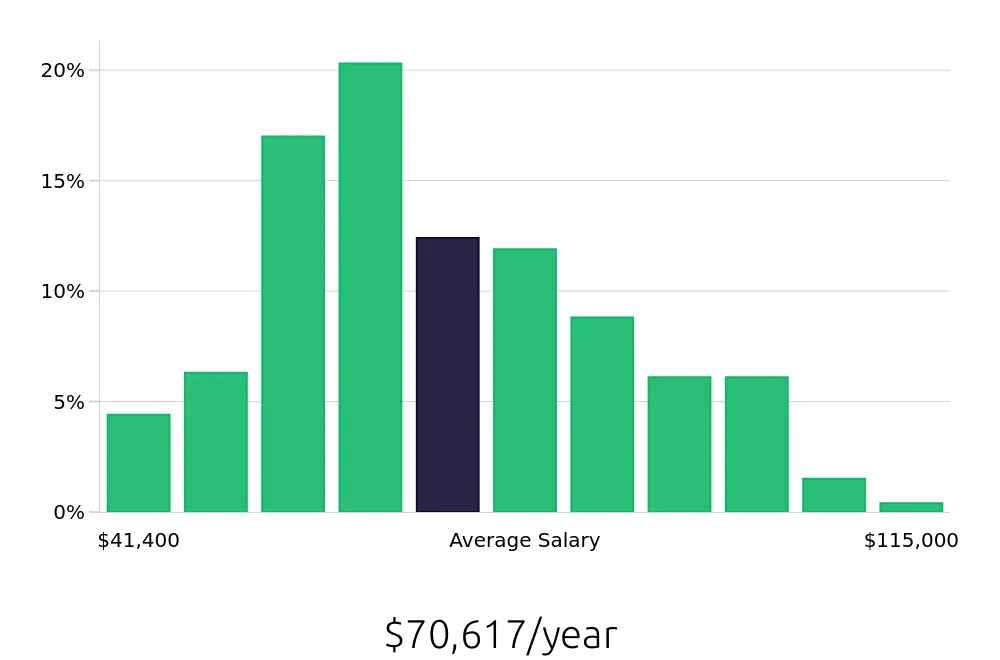

Certified Welding Inspectors enjoy a competitive average annual salary of $49,260 and an hourly rate of $23.68, according to BLS data. These figures highlight the financial rewards and stability associated with a career as a CWI. For job seekers, this presents a viable path with both growth potential and remuneration.

Currently 71 Certified Welding Inspector job openings, nationwide.

Continue to Salaries for Certified Welding Inspector