What does a Extrusion Technician do?

An Extrusion Technician plays a key role in the manufacturing process. They ensure that materials are processed correctly through an extruder. This involves setting up the equipment, monitoring the process, and making adjustments as needed. The technician must understand the properties of different materials and how they behave under pressure. They work closely with engineers to optimize the extrusion process for efficiency and quality. Attention to detail is crucial to avoid defects in the final product.

The Extrusion Technician also maintains the machinery. This includes regular cleaning and performing routine checks. They must be able to identify and fix minor issues quickly. Safety is a top priority. The technician must follow all safety protocols to protect themselves and others. They must also be familiar with the emergency procedures in case of a malfunction. Communication skills are important for working with other team members and reporting any issues to supervisors. This role requires a blend of technical knowledge and practical skills.

How to become a Extrusion Technician?

Becoming an Extrusion Technician involves a series of steps that lead to a rewarding career. This profession requires a mix of technical skills and practical experience. The process starts with gaining the right education and training. It then moves on to acquiring hands-on experience and obtaining necessary certifications. Following these steps can help someone enter this exciting field.

First, a person should complete a high school diploma or GED. Completing courses in math, science, and technology can be very helpful. Next, attending a technical school or community college can provide specialized training in extrusion processes. This training often includes classes on machinery operation, materials science, and safety procedures. Gaining practical experience through internships or entry-level positions is also important. This hands-on work allows someone to learn from experienced professionals and understand the day-to-day operations of an extrusion facility. Finally, obtaining certifications from recognized organizations can enhance job prospects and demonstrate a commitment to the field.

Here are the steps to become an Extrusion Technician:

- Complete a high school diploma or GED.

- Attend a technical school or community college for specialized training.

- Gain practical experience through internships or entry-level positions.

- Learn from experienced professionals in the field.

- Obtain certifications from recognized organizations.

How long does it take to become a Extrusion Technician?

The path to becoming an Extrusion Technician involves several steps. First, a high school diploma or equivalent is necessary. This provides a foundation in basic math and science. Many technicians also complete a vocational training program. These programs can last from a few months to two years. They teach specific skills needed for the job. Some programs offer hands-on experience with real equipment.

After completing a training program, gaining experience is important. Many technicians start in entry-level positions. They work under the supervision of experienced professionals. This helps them learn the job in a real-world setting. Some technicians choose to get certified. This can improve job prospects and earning potential. Certification often requires passing an exam. It shows that the technician has the necessary skills and knowledge.

Extrusion Technician Job Description Sample

The Extrusion Technician is responsible for operating and maintaining extrusion equipment to produce plastic or metal products. This role involves monitoring the production process, troubleshooting equipment issues, and ensuring product quality and safety standards are met.

Responsibilities:

- Operate and maintain extrusion machinery to produce high-quality plastic or metal products.

- Monitor the production process and adjust settings as necessary to ensure product specifications are met.

- Perform routine maintenance and troubleshooting on extrusion equipment to minimize downtime.

- Conduct quality control checks on finished products to ensure they meet company standards.

- Collaborate with engineers and other technicians to improve production processes and equipment efficiency.

Qualifications

- High school diploma or equivalent; technical training or degree in mechanical engineering, manufacturing, or a related field is preferred.

- Proven experience as an Extrusion Technician or similar role in a manufacturing environment.

- Strong understanding of extrusion processes and equipment.

- Proficiency in operating and maintaining extrusion machinery and related tools.

- Ability to read and interpret technical manuals, blueprints, and production specifications.

Is becoming a Extrusion Technician a good career path?

An Extrusion Technician plays a key role in the manufacturing industry. This role involves working with machinery to produce materials like plastics, metals, and food products. Technicians must understand how to operate and maintain the equipment. They also need to ensure that the final product meets quality standards. This job often requires a mix of technical skills and hands-on experience. It can be a rewarding career for those who enjoy working with their hands and solving problems.

Working as an Extrusion Technician has many benefits. It offers a stable job with good pay. Technicians often have opportunities for advancement and training. The job can be fulfilling for those who take pride in their work. However, there are also some challenges to consider. The work can be physically demanding and may require long hours. Technicians must also stay updated with new technologies and safety practices. Understanding these pros and cons can help job seekers decide if this career is right for them.

Here are some pros and cons of being an Extrusion Technician:

- Pros:

- Stable job with good pay

- Opportunities for advancement and training

- Fulfilling work for those who enjoy hands-on tasks

- Variety of industries to work in

- Cons:

- Physically demanding work

- May require long hours

- Need to stay updated with new technologies

- Potential exposure to hazardous materials

What is the job outlook for a Extrusion Technician?

The job outlook for Extrusion Technicians shows a steady demand in the industry. The Bureau of Labor Statistics (BLS) reports an average of 6,300 job positions available each year. This consistent number indicates a reliable career path for those entering the field. With a stable job market, professionals can expect opportunities to arise regularly.

While the job openings percent change from 2022 to 2032 is projected to decrease by 3.9%, this slight decline does not suggest a lack of opportunities. The manufacturing sector continues to evolve, and skilled Extrusion Technicians remain in demand. This role requires specialized knowledge and skills, ensuring that qualified candidates will find employment. The BLS data highlights the importance of continuous learning and skill development in this field.

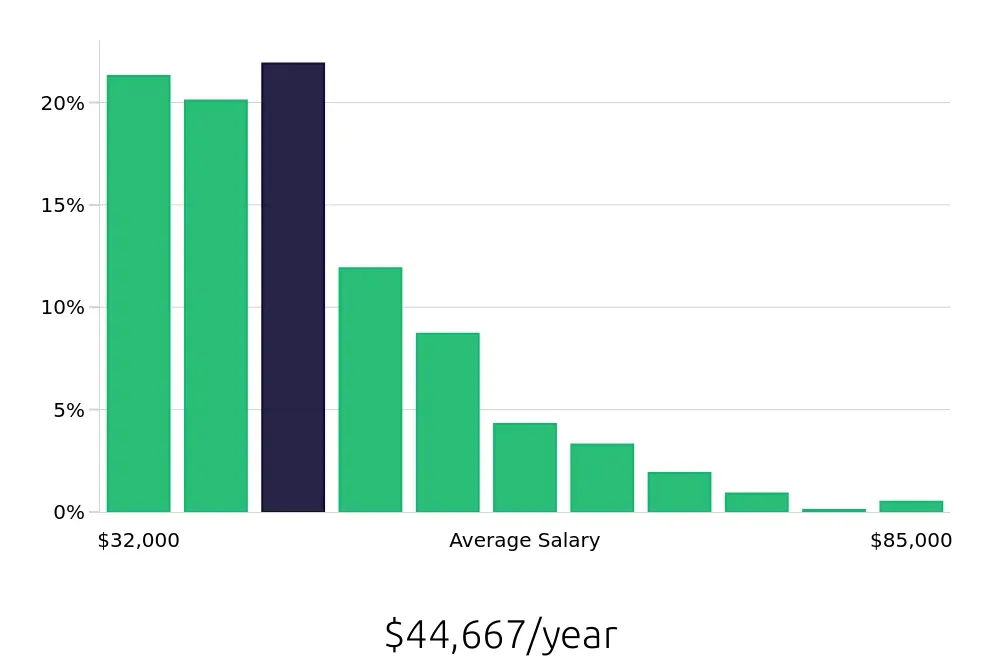

Extrusion Technicians can expect a competitive salary, with an average national annual compensation of $44,020. Hourly, the average wage stands at $21.17. These figures reflect the value placed on the expertise and technical abilities of professionals in this role. Job seekers can anticipate a rewarding career with good financial prospects. The combination of steady job availability and a respectable salary makes this a promising career choice.

Currently 70 Extrusion Technician job openings, nationwide.

Continue to Salaries for Extrusion Technician