What does a Fabrication Operator do?

A Fabrication Operator plays a key role in the manufacturing and construction industries. This professional works with metal and other materials to create parts and structures. Tasks often include cutting, bending, and welding metal to exact specifications. They use a variety of tools and machinery to transform raw materials into finished products. Attention to detail is crucial to ensure the accuracy and quality of each piece produced.

The work environment for a Fabrication Operator can vary. They may work in a factory setting, outdoors on construction sites, or in workshops. Safety is a top priority, as they often handle heavy equipment and materials. A Fabrication Operator must follow strict safety guidelines to protect themselves and others. Strong physical stamina and manual dexterity are important for performing tasks efficiently. This position offers opportunities for those who enjoy hands-on work and problem-solving.

How to become a Fabrication Operator?

Starting a career as a Fabrication Operator can be a rewarding path. This profession involves creating and assembling parts using various materials. Below are key steps to become a Fabrication Operator.

First, gaining relevant education is crucial. Most employers prefer candidates with a high school diploma or equivalent. Some may require specialized training. This could be through vocational schools or apprenticeships. These programs teach essential skills like welding, cutting, and reading blueprints.

- Get Education and Training: Attend a high school or vocational program. Learn skills needed for welding, cutting, and blueprint reading.

- Consider Certifications: Obtain certifications if possible. These add value and show commitment. Look for programs recognized by industry standards.

- Gain Experience: Seek entry-level positions. Work as an assistant or intern. Gain hands-on experience in a workshop or factory setting.

- Enhance Skills: Keep learning new techniques. Attend workshops or online courses. Stay updated with the latest technology and tools.

- Network with Professionals: Join industry groups. Attend trade shows and events. Networking can lead to job opportunities and valuable advice.

How long does it take to become a Fabrication Operator?

Interested in a career as a Fabrication Operator? It's a rewarding path with varied opportunities. The timeline to enter this field often depends on personal goals and the chosen training path. Many people find the journey manageable and fulfilling. Those opting for formal training programs may complete their education in about two years. This includes completing a combination of classroom instruction and hands-on experience.

On the other hand, apprenticeships offer a hands-off approach. These programs merge on-the-job training with classroom learning. They usually last around three to four years. Some apprentices may advance faster and find work sooner, depending on their performance and opportunities. Gaining experience in related jobs or trades can also shorten the path to becoming a Fabrication Operator. This experience brings valuable skills and knowledge to the table, making the transition smoother.

Fabrication Operator Job Description Sample

A Fabrication Operator is responsible for operating and maintaining machinery used to fabricate materials and components for products. They interpret blueprints, use various tools, and ensure quality standards are met throughout the fabrication process.

Responsibilities:

- Operate machinery to cut, shape, and assemble metal and other materials.

- Interpret blueprints and technical drawings to create and produce components.

- Conduct quality control checks to ensure products meet specifications.

- Maintain and troubleshoot machinery to ensure efficient operation.

- Adhere to safety protocols and guidelines to prevent accidents and injuries.

Qualifications

- High school diploma or equivalent required; technical training preferred.

- Experience in operating fabrication machinery and tools.

- Strong understanding of blueprints and technical drawings.

- Ability to work independently and as part of a team.

- Excellent attention to detail and problem-solving skills.

Is becoming a Fabrication Operator a good career path?

A Fabrication Operator plays a key role in manufacturing and construction. This worker uses machines to shape metal and other materials into useful parts. It’s a hands-on job that requires skill and attention to detail. People in this role often work in factories, construction sites, and workshops. They follow blueprints and use tools like welders and saws.

Working as a Fabrication Operator offers many benefits. The job provides steady work in various industries. It also offers the chance to learn new skills and work with advanced machinery. Some operators may have opportunities to travel for projects. However, the job has its challenges. It can be physically demanding and requires working in different environments. Operators must follow strict safety rules to avoid injury. The job can also involve long hours and shifts, especially during busy times.

Here are some pros and cons of being a Fabrication Operator:

- Pros:

- Steady employment in various industries.

- Opportunities to learn and use new skills.

- Potential for travel depending on the project.

- Good pay for skilled labor.

- Cons:

- Physical demands and need for good health.

- Exposure to various environments and conditions.

- Strict safety rules to follow.

- Potential for long hours and shift work.

What is the job outlook for a Fabrication Operator?

The job outlook for Fabrication Operators offers several positive signs for job seekers. On average, around 26,100 job openings are available each year. While there may be a projected decrease of 10.8% in job openings from 2022 to 2032 according to the Bureau of Labor Statistics (BLS), this still presents a stable opportunity for those in the field. This role remains important across various industries, including manufacturing and construction.

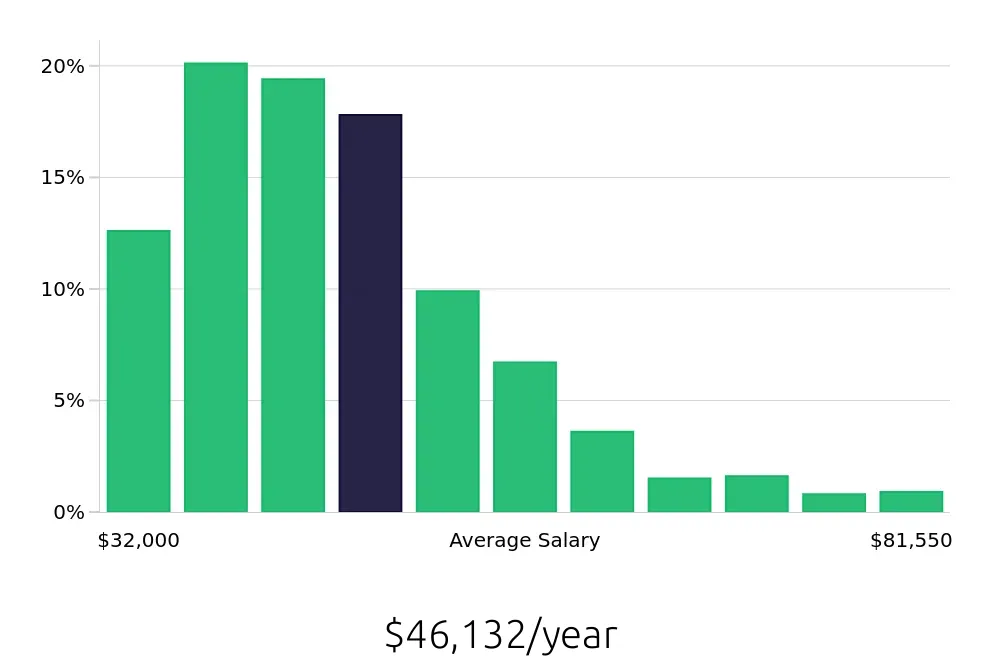

Fabrication Operators have the chance to earn a competitive salary. The BLS reports an average national annual compensation of $44,950. This figure highlights the potential for a rewarding career. Additionally, the average hourly compensation stands at $21.61, reflecting the value placed on skilled labor in this industry. Job seekers can expect a fair return on their investment in training and experience.

For those considering a career as a Fabrication Operator, this sector continues to offer viable opportunities. Despite some projected changes in job availability, the consistent demand for skilled workers remains strong. Job seekers with the necessary training and certifications can look forward to a steady career with good compensation and growth potential.

Currently 133 Fabrication Operator job openings, nationwide.

Continue to Salaries for Fabrication Operator