What does a Furnace Operator do?

A Furnace Operator plays a crucial role in manufacturing and industrial settings. They are responsible for overseeing the operation of furnaces that heat materials to specific temperatures. This position ensures the efficient and safe production of high-quality products. The Furnace Operator monitors the temperature and pressure inside the furnace and adjusts settings to achieve optimal results. They also conduct routine maintenance on the equipment to prevent breakdowns.

Key duties of a Furnace Operator include loading and unloading materials into the furnace, operating control panels, and recording data. They must follow strict safety protocols to protect themselves and others from potential hazards. Attention to detail and the ability to follow instructions carefully are essential for this role. A successful Furnace Operator works closely with other team members to maintain smooth production operations. This position requires a blend of technical skills and hands-on experience in operating industrial equipment.

To excel in this role, a Furnace Operator needs to have a solid understanding of machinery and safety procedures. They should also be able to work in a fast-paced environment and manage multiple tasks at once. This position offers an opportunity to be part of a dynamic team and contribute to the production process in a meaningful way.

How to become a Furnace Operator?

Becoming a furnace operator involves several steps. This profession offers stable employment and good pay. It requires specific skills and knowledge. Follow these steps to pursue this career.

First, gain a high school diploma or GED. Most employers require this basic education. Learn math, science, and mechanical skills in school. These classes help understand furnace operations. Second, complete on-the-job training. This training often lasts several months. Workers learn to monitor temperatures and adjust settings. They also learn safety protocols.

- Obtain a high school diploma or GED.

- Complete on-the-job training, usually several months.

- Get a furnace operator certification if required by the employer.

- Apply for furnace operator positions.

- Continue training and stay updated on industry standards.

Next, obtain a furnace operator certification if required by the employer. Certifications prove knowledge and skills. They make candidates more competitive. Certifications cover safety practices and equipment use. Fourth, apply for furnace operator positions. Use job boards and company websites. Highlight relevant education and training.

Finally, continue training and stay updated on industry standards. Attend workshops and seminars. Keep up with new technologies. This ongoing education helps maintain skills and knowledge. It also leads to career advancement.

How long does it take to become a Furnace Operator?

Pursuing a career as a furnace operator involves specific steps and training. The path can vary based on experience and education. Generally, it takes about one to four years to gain the necessary skills and qualifications.

First, many people start with a high school diploma or GED. Some schools offer training programs that can last up to two years. These programs cover topics like safety, equipment maintenance, and basic operations. On-the-job training is also crucial. Employers often provide this training, which can take several months to a year. In some cases, individuals may start as helpers and work their way up to becoming a full-fledged furnace operator. Experience gained in related roles, such as mechanical or electrical work, can also shorten the time required.

Furnace Operator Job Description Sample

A Furnace Operator is responsible for overseeing the operation of industrial furnaces to ensure efficient production processes. They are tasked with monitoring furnace temperatures, adjusting controls, and performing routine maintenance on furnace equipment to maintain high standards of quality and safety.

Responsibilities:

- Monitor and control furnace temperatures, pressures, and other critical parameters.

- Operate, adjust, and maintain furnace controls to ensure optimal performance.

- Inspect furnace equipment and perform routine maintenance to prevent breakdowns and ensure safety.

- Prepare materials for furnace processing and load and unload furnaces as required.

- Follow all safety protocols and guidelines to maintain a safe working environment.

Qualifications

- High school diploma or equivalent required; technical training or certification in heating and ventilation, industrial processes, or a related field is a plus.

- Proven experience as a Furnace Operator or in a similar role within an industrial setting.

- In-depth knowledge of furnace operation, maintenance, and safety protocols.

- Strong attention to detail and the ability to operate complex machinery with precision.

- Good problem-solving skills and the ability to think critically in high-pressure situations.

Is becoming a Furnace Operator a good career path?

Working as a Furnace Operator involves managing the temperature and flow of materials in industrial furnaces. This role plays a key part in manufacturing, ensuring that products meet quality standards. Operators monitor various gauges and controls, making adjustments as needed to maintain optimal conditions. This career offers the chance to work in a variety of industries, including steel, glass, and ceramics.

Furnace Operators face both rewarding and challenging aspects in their job. They enjoy stable employment in essential industries and often receive good benefits. This career also offers the chance to gain experience in a hands-on environment. On the downside, the job can be physically demanding and may involve working long hours. Operators also need to handle high temperatures and hazardous materials, which can be risky. Understanding these pros and cons helps in making an informed career choice.

Below are some pros and cons to consider if you are thinking about becoming a Furnace Operator:

- Pros:

- Stable employment in essential industries.

- Good benefits and pay.

- Hands-on experience in a critical role.

- Cons:

- Physical demands and long hours.

- Risks from working with high temperatures and hazardous materials.

- Potential exposure to noise and dust.

What is the job outlook for a Furnace Operator?

The job outlook for Furnace Operators looks promising, with an average of 1,800 job openings each year, according to the Bureau of Labor Statistics (BLS). This steady demand shows that many industries rely on skilled Furnace Operators. Job seekers can expect to find many opportunities in this field.

The BLS also reports a projected 0.4% increase in job openings for Furnace Operators from 2022 to 2032. This modest growth suggests consistent demand for this profession. Job seekers should be able to find stable employment options.

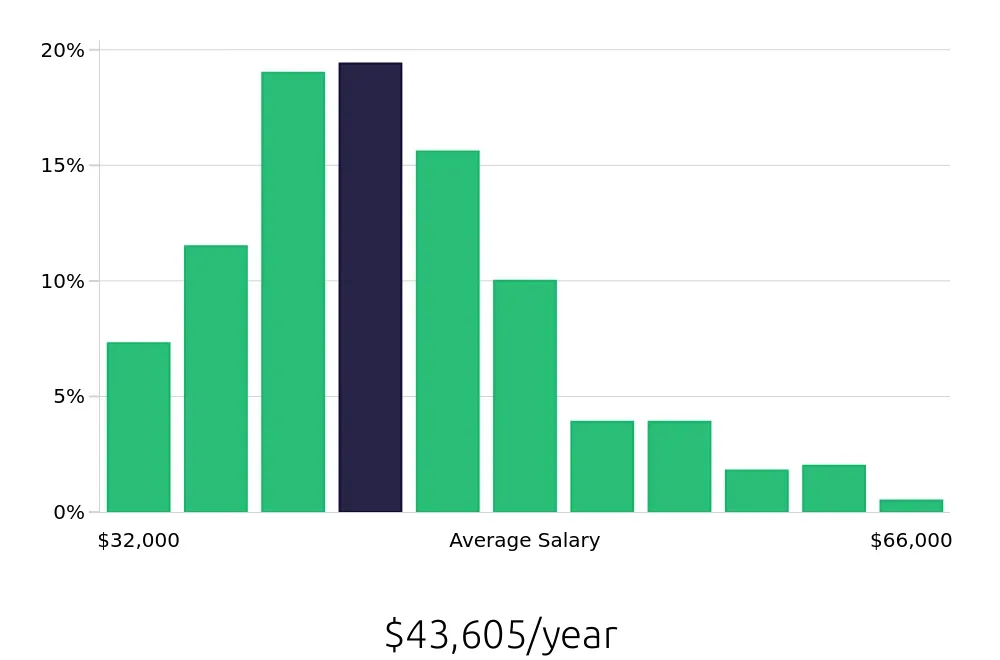

Furnace Operators enjoy a competitive salary, with an average national annual compensation of $47,540. This amounts to about $22.86 per hour, according to the BLS. These figures make the role an attractive option for those seeking a steady income in a high-demand industry.

Currently 55 Furnace Operator job openings, nationwide.

Continue to Salaries for Furnace Operator