What does a Heavy Forging Machine Operator do?

A Heavy Forging Machine Operator works with large machinery to shape metal. This person operates equipment that molds hot metal into specific forms. They use tools and machines to ensure the metal meets the required dimensions and quality standards. Their work is vital for industries that need strong, custom metal parts.

This position demands careful attention to detail and a solid understanding of machine operations. Operators follow safety protocols to protect themselves and others. They work closely with engineers and other team members to meet production goals. Each day, they start by inspecting the machine for any issues and then proceed to load and unload metal pieces. The work can be physically demanding but offers the satisfaction of creating useful metal components.

How to become a Heavy Forging Machine Operator?

Becoming a Heavy Forging Machine Operator requires dedication and the right steps. This role is crucial in manufacturing, where operators play a key role in creating metal parts. The path to this career includes education, training, and experience. Follow these steps to start a successful career in heavy forging.

Firstly, a high school diploma or equivalent is necessary. Basic math and science skills are important. Next, an apprenticeship or vocational training program provides hands-on experience. These programs usually last two to four years. During this time, operators learn to use machines and understand metalwork. Hands-on training is essential for mastering the skills needed.

- Obtain a high school diploma or GED.

- Enroll in an apprenticeship or vocational training program.

- Complete the training program and gain experience.

- Consider obtaining certifications for safety and machine operation.

- Apply for jobs in manufacturing or metalworking companies.

Finally, certifications can boost job prospects. Certifications in safety and machine operation show a commitment to quality and safety. Job seekers with these certifications often have an advantage. Operators can find employment in various industries, including automotive, aerospace, and construction.

How long does it take to become a Heavy Forging Machine Operator?

The path to becoming a Heavy Forging Machine Operator involves a mix of education, training, and hands-on experience. Typically, an aspiring operator will need to complete a high school diploma or equivalent. After that, the journey to proficiency includes several steps. Individuals often attend a technical school or community college for formal training programs that last from a few months to a couple of years.

During this time, students learn about the machinery, safety protocols, and the principles of metalworking. Some programs offer apprenticeships, allowing learners to work under experienced operators while gaining practical skills. Most programs combine classroom instruction with on-the-job training. This ensures that operators are well-prepared to handle the responsibilities of the role.

Once the formal education and training are complete, operators might start in entry-level positions. They gain more experience and skill over time, often improving their chances for advancement and higher pay. This journey, while structured, highlights the dedication and commitment needed to excel in this specialized field.

Heavy Forging Machine Operator Job Description Sample

The Heavy Forging Machine Operator is responsible for operating and maintaining heavy forging machines to produce high-quality metal parts. The role involves ensuring the machines are running efficiently and safely, and adhering to production schedules and quality standards.

Responsibilities:

- Operate heavy forging machines to manufacture metal parts according to specifications.

- Set up and adjust machines to ensure correct operation and optimal performance.

- Monitor machine operations to detect any irregularities or malfunctions.

- Perform routine maintenance and troubleshooting on forging machines.

- Inspect and record machine performance and report any issues to the maintenance team.

Qualifications

- High school diploma or equivalent required; technical or vocational training preferred.

- Proven experience as a Heavy Forging Machine Operator or similar role.

- Knowledge of forging processes and machine operation.

- Understanding of maintenance procedures and troubleshooting techniques.

- Strong attention to detail and ability to follow technical instructions.

Is becoming a Heavy Forging Machine Operator a good career path?

A Heavy Forging Machine Operator plays a key role in manufacturing. This job involves running and maintaining large machines that shape metal into tools and parts. Operators must follow safety rules and ensure the machines run smoothly. This career offers a mix of manual and technical skills.

Working as a Heavy Forging Machine Operator has its benefits and challenges. Let’s look at some pros and cons to consider.

- Pros:

- Stable Employment: Many industries need skilled operators.

- Good Pay: This job often comes with competitive wages.

- Skill Development: Operators learn to handle and maintain complex machinery.

- Cons:

- Physical Demands: The job can be physically demanding and require standing for long hours.

- Noise: Working with heavy machinery can be loud and may require hearing protection.

- Safety Risks: There is always a risk of injury due to the nature of the equipment.

Considering these points helps job seekers decide if this career is a good fit for them.

What is the job outlook for a Heavy Forging Machine Operator?

The role of a Heavy Forging Machine Operator offers a stable career path with steady demand. On average, around 9,600 new job positions open each year. This position remains important in industries that require heavy machinery for manufacturing. Despite a projected decrease of 5.7% in job openings from 2022 to 2032, the role continues to provide opportunities. Job seekers can expect consistent job availability in various sectors.

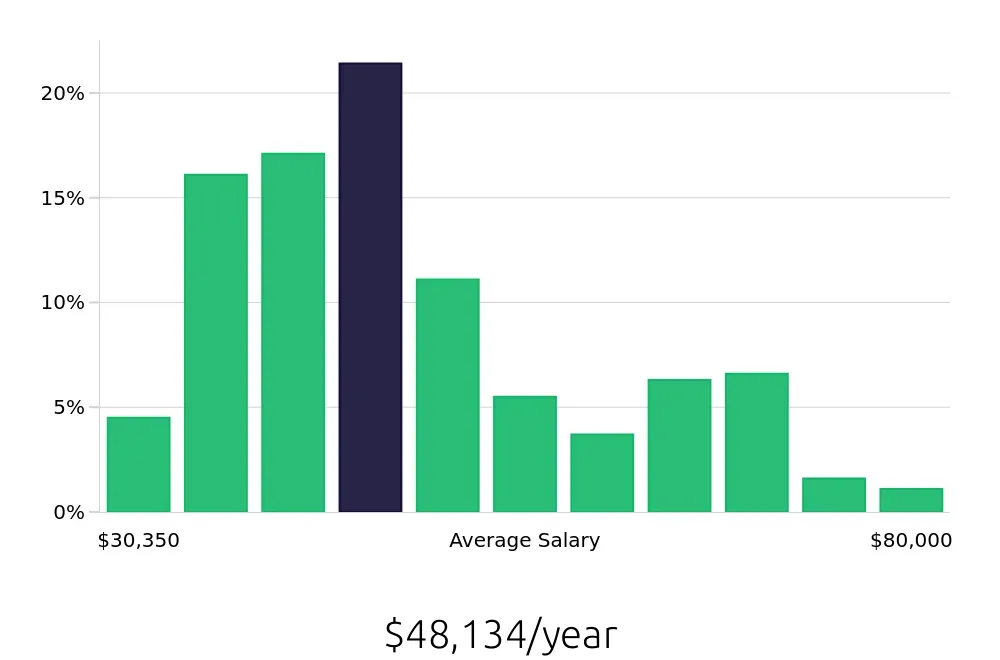

Heavy Forging Machine Operators can look forward to a competitive salary. The average annual compensation stands at $46,600. Hourly pay averages around $22.4. This reflects the value of skilled workers in operating and maintaining heavy machinery. These figures offer a clear picture of the financial benefits for those in this field. Potential earnings make this career attractive to job seekers considering a future in industrial manufacturing.

Interested individuals should note the consistent demand for skilled Heavy Forging Machine Operators. Although the number of job openings may decline slightly, the role remains vital. It provides a pathway to a rewarding career with decent compensation. Job seekers with the necessary skills and training can find a stable and lucrative position in this field.

Currently 70 Heavy Forging Machine Operator job openings, nationwide.

Continue to Salaries for Heavy Forging Machine Operator