What does a Instrument Operator do?

An Instrument Operator plays a key role in various industries by handling and maintaining specialized equipment. This professional operates machinery that measures, monitors, and controls processes. They ensure that instruments function correctly to gather accurate data and support the smooth running of operations. Regular calibration and maintenance of equipment are vital tasks. This role requires attention to detail and a solid understanding of how the equipment works.

The duties of an Instrument Operator include setting up and operating devices such as flow meters, pressure gauges, and temperature sensors. They analyze readings and make adjustments as needed. The role often involves working in a team and collaborating with other technicians and engineers. Instrument Operators must follow safety protocols to protect themselves and others. Keeping detailed records of instrument readings and maintenance activities is also a key responsibility. This position demands a reliable individual who can work in dynamic environments.

How to become a Instrument Operator?

Becoming an Instrument Operator is a valuable career choice that opens up many opportunities in various industries. This role involves monitoring and controlling industrial processes using specialized instruments. To embark on this career path, one needs to follow a structured process.

First, obtain a high school diploma or equivalent. This forms the basic educational requirement for most entry-level positions. Next, consider completing a formal training program in instrumentation. These programs are available through trade schools, community colleges, and technical institutes. They provide hands-on experience and theoretical knowledge crucial for the job. After training, gaining practical experience is essential. Seek an apprenticeship or entry-level position with a company that uses industrial instruments. This experience will help build the necessary skills and confidence.

The process of becoming an Instrument Operator includes these key steps:

- Complete high school or a GED.

- Enroll in a training program for instrumentation.

- Gain practical experience through an apprenticeship or entry-level job.

- Obtain certification if required by your state or industry.

- Continue learning and advancing through professional development and networking.

By following these steps, one can successfully become an Instrument Operator and thrive in this dynamic field.

How long does it take to become a Instrument Operator?

The time it takes to become an Instrument Operator can vary based on many factors. Most operators begin with a high school diploma or GED. They then complete a training program. These programs often last between one and four years. Some take longer, while others might be shorter.

During training, individuals learn about various types of instruments. They also study how to read gauges and control systems. A strong focus on safety training is a key part of the program. The length of training can depend on the specific requirements of the industry and the complexity of the instruments being used. Some employers may offer on-the-job training in addition to formal education. This can also affect the total time needed to become fully qualified.

Instrument Operator Job Description Sample

An Instrument Operator is responsible for the operation, calibration, and maintenance of various industrial instruments and control systems to ensure optimal performance and safety in manufacturing and production environments.

Responsibilities:

- Operate and monitor various industrial instruments and control systems to ensure accurate readings and measurements.

- Calibrate instruments according to standard procedures and manufacturer guidelines to maintain accuracy.

- Conduct routine inspections and maintenance of instruments to prevent equipment failure and downtime.

- Troubleshoot and resolve operational issues with instruments and control systems.

- Document instrument readings, maintenance activities, and any issues encountered during operation.

Qualifications

- High school diploma or equivalent; technical certification in instrumentation or related field is preferred.

- Proven experience as an Instrument Operator or similar role in an industrial setting.

- Strong understanding of instrumentation and control systems, including pneumatic, hydraulic, and electronic systems.

- Ability to read and interpret technical manuals, blueprints, and schematics.

- Proficiency in using calibration equipment and tools.

Is becoming a Instrument Operator a good career path?

Being an Instrument Operator means working with specialized equipment to measure, monitor, and control various processes. This role is key in many industries, including manufacturing, oil and gas, and pharmaceuticals. Operators often manage complex machinery that requires precise attention to detail. This job demands technical skills and a strong understanding of the equipment used.

An Instrument Operator enjoys several benefits. For one, the job offers a stable career path with steady demand across many sectors. Training opportunities are often available, allowing operators to learn new skills and advance their careers. Many employers offer competitive wages and benefits packages. However, it’s not without its challenges. Operators work in environments that can be hazardous, requiring strict adherence to safety protocols. The job also demands long hours and can involve working in uncomfortable conditions. Despite these challenges, it remains a fulfilling career for those who enjoy hands-on work and problem-solving.

- Pros:

- Stable career with steady demand

- Opportunities for training and advancement

- Competitive wages and benefits

- Cons:

- Potential exposure to hazardous environments

- Demanding work hours and conditions

- Need for strict adherence to safety protocols

What is the job outlook for a Instrument Operator?

Job seekers interested in becoming an Instrument Operator have a positive outlook ahead of them. Each year, around 7,800 job positions open up in this field. This is according to the U.S. Bureau of Labor Statistics (BLS). This average is expected to grow by 3.3% from 2022 to 2032. This growth shows a steady demand for Instrument Operators.

Instrument Operators play a crucial role in various industries, including manufacturing, oil and gas, and pharmaceuticals. They monitor and control industrial machinery. They ensure everything runs smoothly and safely. This demand for skilled operators remains strong. Companies rely on them to maintain efficiency and safety in production processes. For those considering this career, the consistent job openings and expected growth present a promising opportunity.

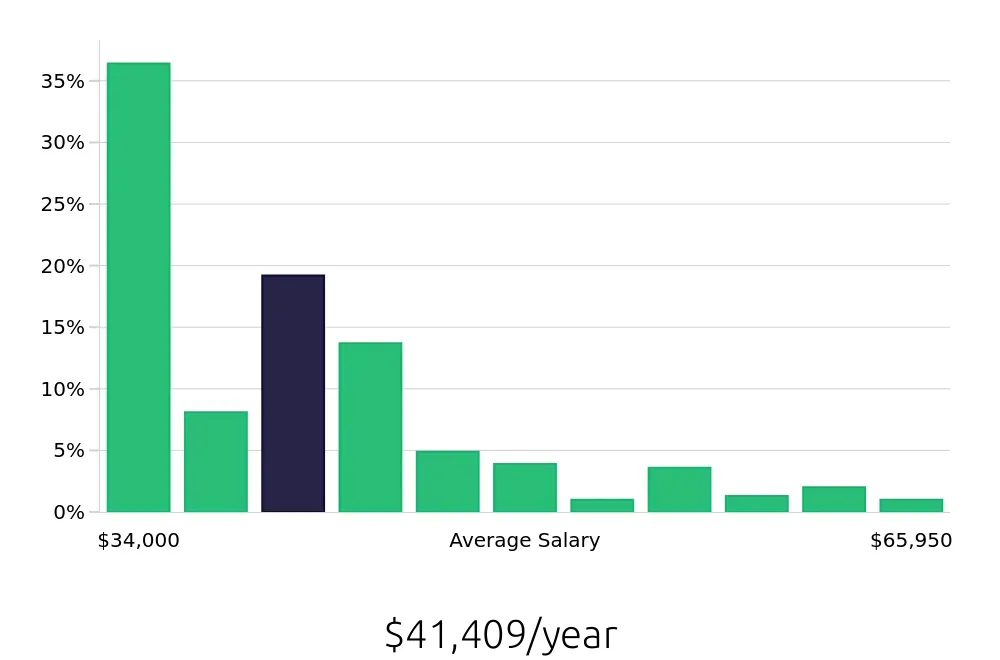

The average national annual compensation for Instrument Operators stands at $54,090. This figure reflects the value placed on their expertise and responsibilities. On an hourly basis, the compensation averages about $26. These figures provide a clear picture of the financial rewards that come with this profession. Job seekers can expect a stable income. This, combined with the positive job outlook, makes this career path an attractive choice for many.

Currently 40 Instrument Operator job openings, nationwide.

Continue to Salaries for Instrument Operator