What does a Lamination Operator do?

A Lamination Operator plays a vital role in producing quality laminated products. This position involves working with high-speed lamination machines to combine different materials. The operator ensures that each layer adheres properly and that the final product meets all specifications. Attention to detail is crucial to avoid any defects in the lamination process. The operator also performs routine machine maintenance to keep production running smoothly.

In addition to operating the laminator, this role may include inspecting finished products for quality. The Lamination Operator checks for any imperfections and ensures the product meets the company's standards. They may also prepare materials for lamination and ensure that all necessary supplies are on hand. This role requires precision and a strong commitment to quality. It is ideal for individuals who enjoy working with their hands and paying close attention to detail.

How to become a Lamination Operator?

Becoming a Lamination Operator is a great choice for those who want a stable job in manufacturing. This role involves working with laminates and ensuring they are applied correctly. Follow these steps to start a career as a Lamination Operator.

First, learn about the job. Understand what a Lamination Operator does. This role involves using machinery to apply laminates to materials. It requires precision and attention to detail.

- Get a high school diploma or GED. This is usually the minimum requirement for most jobs.

- Take vocational training courses. These courses teach skills specific to lamination. Look for programs that include hands-on experience.

- Gain experience. Start with entry-level jobs in manufacturing. Look for apprenticeships or internships. This experience is valuable.

- Get certified. Some employers prefer or require certification. Check with local trade organizations for available certifications.

- Apply for jobs. Look for job openings in your area. Use job boards, company websites, and recruitment agencies.

How long does it take to become a Lamination Operator?

Lamination involves applying protective films or coatings to various materials. It is a sought-after skill in many industries. To start working as a Lamination Operator, one needs to understand both the time and effort required. Most people find it takes about six months to a year to get ready for this role.

Training programs usually last between three months and a year. These programs teach essential skills. They cover how to operate lamination machines, apply coatings correctly, and ensure quality. Some programs offer on-the-job training. This can shorten the learning curve. Individuals who complete these programs often find themselves well-prepared. They can then start working as Lamination Operators. Companies value these trained professionals. They quickly understand the tools and techniques needed for the job.

Experienced workers often share tips to help new operators. Tips can range from safety practices to efficiency tricks. They highlight the importance of attention to detail. This skill is crucial in ensuring the quality of laminated products. The journey to becoming a Lamination Operator is clear and achievable. It leads to a rewarding and stable career path.

Lamination Operator Job Description Sample

A Lamination Operator is responsible for overseeing and managing the lamination process in a manufacturing setting. This involves using various laminating machines to combine materials such as paper, foil, and plastic. The operator ensures the quality and precision of the lamination process and maintains the machinery and equipment used in the process.

Responsibilities:

- Operate and monitor laminating machines to combine materials such as paper, foil, and plastic.

- Ensure the accuracy and quality of the lamination process by adhering to specifications.

- Maintain and perform routine maintenance on lamination equipment to ensure optimal performance.

- Inspect laminated products for defects and ensure that they meet quality standards.

- Adjust machine settings and parameters to achieve desired lamination results.

Qualifications

- High school diploma or equivalent required; vocational training in a related field is preferred.

- Previous experience as a Lamination Operator or in a similar role.

- Knowledge of lamination processes and materials.

- Understanding of machine operation, maintenance, and troubleshooting.

- Strong attention to detail and quality control skills.

Is becoming a Lamination Operator a good career path?

Lamination operators play a key role in various industries, from packaging to manufacturing. These professionals use specialized machines to apply layers of material to a product. This process enhances durability, appearance, and protection. The work requires precision and attention to detail, making it suitable for those who enjoy hands-on tasks.

Lamination operators benefit from a stable job market with growth potential. The increasing demand for packaged goods and protective materials opens up many opportunities. The role offers a clear career path, with potential to advance to supervisory or managerial positions. However, the job can be repetitive and physically demanding, which may not suit everyone.

Consider the following pros and cons before pursuing a career as a lamination operator:

- Pros:

- Job stability in various industries

- Clear path for career advancement

- Opportunity to work with advanced machinery

- Cons:

- Repetitive tasks can be monotonous

- Potential for physical strain

- Requires attention to detail and precision

What is the job outlook for a Lamination Operator?

Lamination operators are essential in many industries. This job involves bonding materials like plastic, paper, or metal. The demand for skilled lamination operators remains steady. The Bureau of Labor Statistics (BLS) reports an average of 2,400 job positions opening each year. The outlook shows a slight decrease of 0.3% from 2022 to 2032. Despite this, the field offers many opportunities for job seekers.

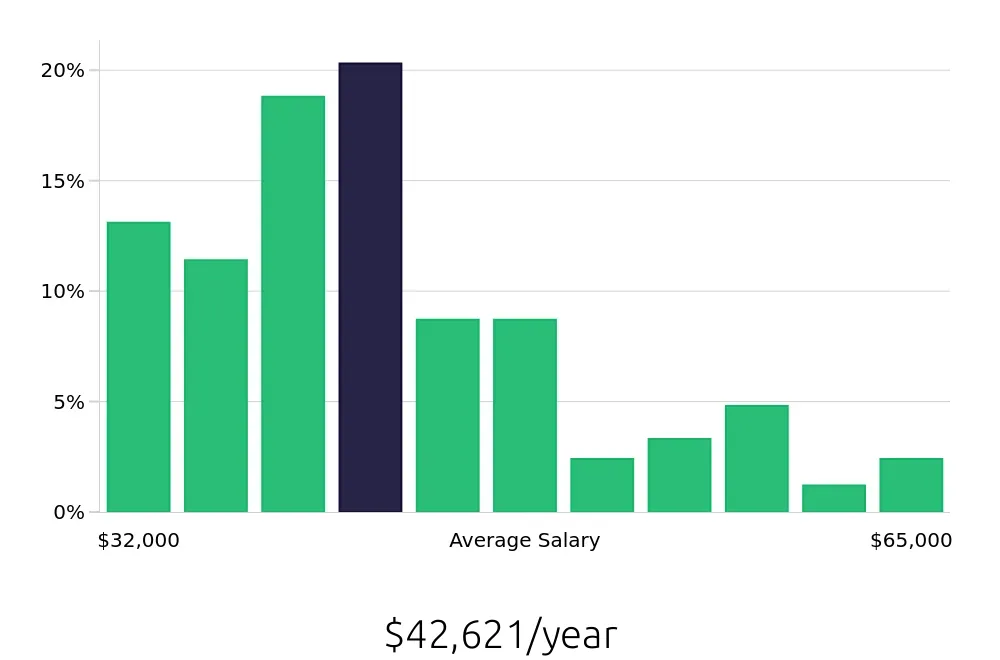

A career as a lamination operator is financially rewarding. The BLS states an average national annual compensation of $43,920. Hourly, the average compensation stands at $21.12. These figures reflect the value of lamination operators in various sectors. Workers gain a stable income, making this a lucrative career choice. Competitive salaries and benefits attract many to this profession.

Interested individuals will find ample job openings. Companies in manufacturing, packaging, and construction need skilled lamination operators. The industry's stability ensures continuous demand. Job seekers with the right skills can find employment easily. Training and certification programs enhance employability. The BLS projects a manageable number of job openings, providing a positive career outlook.

Currently 26 Lamination Operator job openings, nationwide.

Continue to Salaries for Lamination Operator