What does a Lead Caster do?

A Lead Caster works in a foundry, casting metal into molds to create components for machinery and equipment. This person carefully measures and mixes materials to ensure the final product meets the required specifications. They operate casting machines, monitoring the process to avoid defects. This role requires attention to detail and a strong understanding of casting techniques.

The Lead Caster oversees the entire casting process, from preparing the molds to inspecting the finished parts. They coordinate with other team members, ensuring all steps are completed efficiently. This professional must follow safety guidelines to protect themselves and others. Each project requires precision, as the quality of the cast parts can affect the performance of the final product. The Lead Caster plays a crucial role in delivering high-quality metal components for various industries.

How to become a Lead Caster?

Becoming a Lead Caster involves understanding the industry, gaining relevant skills, and positioning oneself effectively within the job market. This role often requires a specific set of abilities, including attention to detail and a strong understanding of casting processes.

Here is a step-by-step guide to help navigate the journey to becoming a Lead Caster:

- Research the Role: Learn about the responsibilities of a Lead Caster. Understand the specific duties and the skills needed for success.

- Gain Relevant Experience: Seek out opportunities to work in casting environments. This may include internships, apprenticeships, or entry-level positions in the industry.

- Develop Essential Skills: Focus on building skills such as attention to detail, knowledge of casting materials, and the ability to work under pressure.

- Network within the Industry: Connect with professionals in the casting field. Attend industry events, join relevant groups, and engage with others who have experience in casting.

- Stay Updated: Keep abreast of the latest trends and technologies in casting. Continuous learning will enhance your skills and make you a more attractive candidate.

How long does it take to become a Lead Caster?

Lead casting involves shaping molten metal into specific forms. This specialized skill requires a mix of education, training, and hands-on experience. Most professionals enter this field after completing a relevant apprenticeship or vocational program. These programs often last two to four years. They provide both classroom instruction and on-the-job training.

During this time, aspiring lead casters learn essential techniques. They gain proficiency in using casting equipment and understanding metal properties. Experience in related areas, such as welding or metal fabrication, can also be beneficial. This combination of formal education and practical experience equips candidates for a career in lead casting. The length of time to become fully proficient can vary. Many find they reach full competency after a few years of working in the industry. Continuous learning and skill development remain important throughout a career in lead casting.

Lead Caster Job Description Sample

The Lead Caster will oversee and direct the casting process for a production, ensuring that the right talent is selected to bring the project's vision to life. This role requires a keen eye for talent, strong leadership skills, and the ability to collaborate effectively with directors, producers, and other key stakeholders.

Responsibilities:

- Oversee the entire casting process from sourcing actors to final selection.

- Collaborate with directors, producers, and other stakeholders to understand character requirements and project vision.

- Conduct auditions and casting calls to evaluate potential talent.

- Build and maintain a database of actors, including talent profiles and availability.

- Negotiate contracts and manage relationships with talent and agencies.

Qualifications

- Proven experience as a casting director or in a similar role.

- Exceptional ability to evaluate talent and assess suitability for roles.

- Strong leadership and team management skills.

- Excellent negotiation and contract management abilities.

- In-depth knowledge of union regulations and industry standards.

Is becoming a Lead Caster a good career path?

A Lead Caster works in the metal industry, specifically with metal casting. This role involves creating molds and using them to produce various metal parts. It’s a hands-on job that combines technical skills with creativity. Companies in manufacturing, automotive, and construction often hire Lead Casters. This position requires a solid understanding of materials and precise craftsmanship.

Working as a Lead Caster has its benefits and challenges. The role offers a chance to work with different materials and create essential components for many industries. It’s a job that combines physical labor with technical expertise. However, it can be demanding, requiring long hours and sometimes working in tough conditions. Here are some pros and cons to consider.

Pros of Being a Lead Caster:

- Stability: Many industries rely on metal casting, ensuring steady job opportunities.

- Skill Development: This job allows for the continuous learning and application of new techniques.

- Good Pay: Experienced Lead Casters often earn competitive salaries.

Cons of Being a Lead Caster:

- Physical Demands: The job can be physically challenging, requiring long hours of standing and manual labor.

- Safety Risks: Working with hot metals and heavy equipment can pose safety hazards.

- Limited Mobility: Many positions are factory-based, limiting geographical job opportunities.

What is the job outlook for a Lead Caster?

Job seekers interested in the role of a Lead Caster will find a stable employment market with a steady demand for professionals in this field. According to the Bureau of Labor Statistics (BLS), there are around 2,200 average job positions available per year. This consistent number of job openings suggests a reliable career path for those skilled in casting operations. While the projected job openings are expected to decrease by 8.4% from 2022 to 2032, the role remains crucial for industries that rely on metal casting processes.

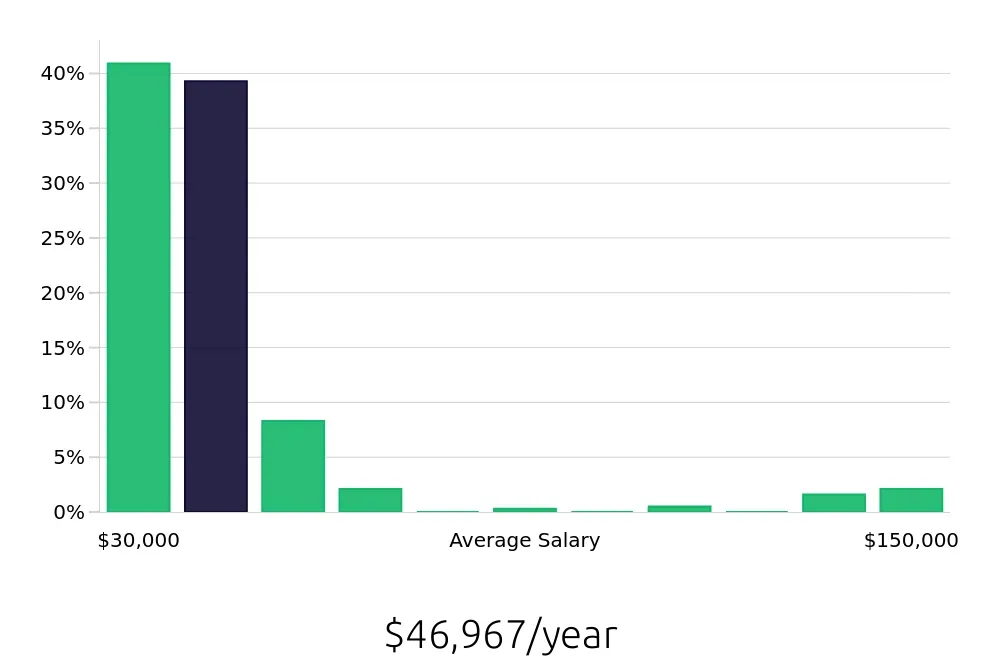

Compensation for Lead Casters is competitive, reflecting the skills and expertise needed for the job. The BLS reports an average national annual salary of $53,460. This translates to an hourly wage of $25.7. These figures highlight the financial rewards that professionals in this field can expect, making it an attractive career choice for those with the necessary qualifications. Job seekers can look forward to earning a fair salary that reflects their valuable contributions to manufacturing and production processes.

The path to becoming a Lead Caster involves gaining practical experience and possibly formal training. This career path offers growth opportunities within the industry. Prospective Lead Casters should be prepared to develop their skills and stay updated with the latest technologies and techniques in metal casting. With a clear job outlook and good compensation, this profession provides a solid foundation for long-term career development.

Currently 156 Lead Caster job openings, nationwide.

Continue to Salaries for Lead Caster