What does a Machine Technician do?

A Machine Technician plays a crucial role in ensuring that machinery operates smoothly and efficiently. They inspect machines, identify issues, and perform repairs. Technicians also maintain logs of all maintenance activities to ensure equipment is properly cared for. The job involves using various tools and equipment to carry out tasks. Machine Technicians must understand technical manuals and schematics to perform their duties accurately.

These professionals work closely with other team members to diagnose problems and implement solutions. They may need to collaborate with engineers or other technicians when dealing with complex repairs. Machine Technicians must adhere to safety protocols to protect themselves and others from injury. Attention to detail and problem-solving skills are essential for this role. A Machine Technician must stay updated with the latest technology and techniques to perform their job effectively.

How to become a Machine Technician?

Becoming a Machine Technician opens many doors in the manufacturing and maintenance industries. This role involves repairing and maintaining equipment. It also requires knowledge of machinery and tools. Follow these steps to start your journey as a Machine Technician.

First, gain a high school diploma or GED. This is the basic requirement. Most employers expect this minimum education level. Next, find a training program. Technical schools and community colleges offer courses in machine technology. These programs teach essential skills. They cover topics from basic mechanics to advanced diagnostics.

- Get a High School Diploma or GED: This is the starting point. It provides the foundational knowledge needed.

- Enroll in a Training Program: Look for programs that offer hands-on experience. These programs should cover both theoretical and practical aspects of machine technology.

- Complete an Apprenticeship: Many technicians learn on the job. Apprenticeships offer real-world experience. They allow you to work under experienced technicians.

- Gain Certifications: Obtain certifications from recognized organizations. These prove your skills and knowledge. Examples include the NATE certification for HVAC technicians.

- Continue Learning: Technology evolves quickly. Stay updated with new tools and techniques. Attend workshops and seminars. This keeps your skills sharp.

How long does it take to become a Machine Technician?

The journey to becoming a Machine Technician varies based on education and experience. Most technicians start with a high school diploma or equivalent. They may choose to attend a trade school or community college for specialized training. This training usually takes one to two years.

Those with prior experience in related fields might find shorter paths to certification. Continuing education and on-the-job training often play key roles in gaining proficiency. Most Machine Technicians find that they can perform their duties well within a few years. Experience and ongoing education can lead to more advanced positions over time.

Here are some steps to consider:

- Complete high school or a GED.

- Enroll in a vocational school or community college program.

- Gain hands-on experience through apprenticeships or entry-level jobs.

- Obtain certifications to enhance job prospects.

Machine Technician Job Description Sample

We are seeking a skilled Machine Technician to join our team. The ideal candidate will be responsible for maintaining and repairing various types of machinery, ensuring equipment runs smoothly and efficiently. This role requires a hands-on approach and a strong commitment to safety and quality.

Responsibilities:

- Perform routine maintenance and repairs on machinery to ensure optimal performance.

- Diagnose mechanical issues and implement corrective actions.

- Conduct inspections and tests to identify potential problems before they escalate.

- Follow safety protocols and maintain a clean and organized work area.

- Collaborate with other team members to meet production goals and deadlines.

Qualifications

- High school diploma or equivalent required; technical degree or certification preferred.

- Proven experience as a Machine Technician or similar role.

- Strong understanding of mechanical and electrical systems.

- Proficiency in using diagnostic tools and equipment.

- Excellent problem-solving skills and attention to detail.

Is becoming a Machine Technician a good career path?

Working as a machine technician offers a blend of practical skills and technical knowledge. This role involves maintaining, repairing, and troubleshooting a variety of machines and equipment. Technicians often work in factories, construction sites, and repair shops. They play a crucial part in ensuring that operations run smoothly. Companies value technicians who can diagnose issues quickly and provide effective solutions.

Choosing a career as a machine technician has both benefits and challenges. Understanding these can help you decide if this is the right path for you. Below are some pros and cons to consider.

- Pros:

- Stability: Demand for skilled technicians remains steady across many industries.

- Hands-on work: Technicians get to work directly with their hands, making tasks practical and engaging.

- Opportunity to learn: Constant learning about new technologies and equipment is part of the job.

- Career advancement: Technicians can move into supervisory roles or specialize in specific types of equipment.

- Cons:

- Physical demands: The job can be physically demanding and may involve long hours on your feet.

- Irregular hours: Technicians may need to work evenings, weekends, or be on-call for emergencies.

- Risk of injury: There is always a risk of injury from working with heavy machinery and tools.

- Continual training: Keeping up with the latest technologies and safety standards requires ongoing education.

What is the job outlook for a Machine Technician?

The job outlook for Machine Technicians shows positive trends for the future. The Bureau of Labor Statistics (BLS) reports around 13,600 job positions per year. This offers ample opportunity for qualified job seekers. The BLS also projects a 0.6 percent change in job openings from 2022 to 2032, indicating steady demand in this field. With these numbers, those entering or transitioning into this career can look forward to a stable job market.

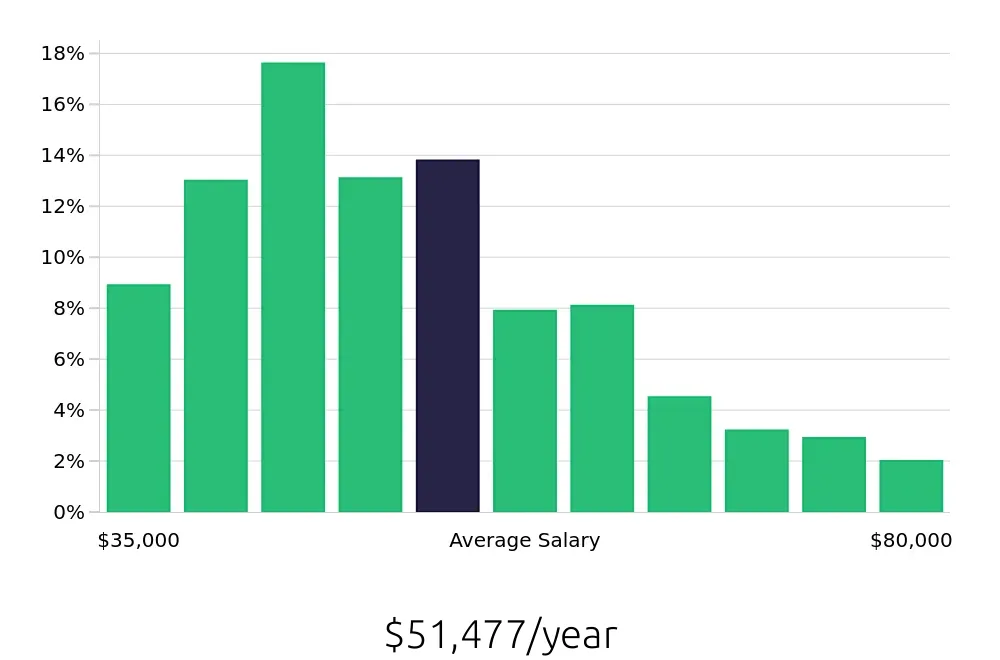

Earnings for Machine Technicians are another strong incentive for job seekers. The average national annual compensation stands at $43,990, according to BLS data. This figure reflects the potential for a solid income. On an hourly basis, the average compensation is $21.15. These numbers provide a clear picture of the financial rewards that come with this profession. Job seekers can expect both stability and fair compensation in this field.

Machine Technicians will find a mix of job security and growth opportunities. The steady number of job openings and positive salary data make this an attractive career path. Job seekers with the necessary skills and qualifications can benefit from these trends. This outlook promises a rewarding career with good financial prospects.

Currently 111 Machine Technician job openings, nationwide.

Continue to Salaries for Machine Technician