What does a Manufacturing Engineer do?

A Manufacturing Engineer focuses on improving the production processes within a manufacturing company. They work to design efficient manufacturing systems, ensuring that products are made with high quality and at the lowest possible cost. These professionals analyze current production methods and implement new technologies or practices to enhance efficiency.

Key responsibilities include overseeing the operation of machinery and equipment, troubleshooting production issues, and collaborating with other departments to streamline operations. They also conduct regular maintenance on equipment to prevent downtime. By leveraging their technical skills and problem-solving abilities, Manufacturing Engineers play a crucial role in achieving company goals and meeting customer demands. Their work directly impacts the speed and quality of production, making them essential members of the manufacturing team.

How to become a Manufacturing Engineer?

Becoming a Manufacturing Engineer involves a mix of education, training, and practical experience. This career path can lead to a rewarding job in the industrial sector. Follow these steps to embark on the journey to becoming a Manufacturing Engineer.

First, a solid educational foundation is crucial. Manufacturing Engineers typically need at least a bachelor's degree in mechanical engineering, industrial engineering, or a related field. Look for accredited programs that offer hands-on learning. Courses in materials science, thermodynamics, and design are especially useful.

- Earn a relevant degree: Start with a bachelor's degree in engineering.

- Gain practical experience: Look for internships or co-op programs during college.

- Get licensed: Consider obtaining a Professional Engineer (PE) license if needed.

- Network with professionals: Join engineering associations and attend industry events.

- Continue learning: Stay updated with the latest trends and technologies.

After obtaining a degree, seek internships or co-op programs. These experiences provide valuable real-world skills and help build a resume. Employers often value candidates with practical experience. Networking is another key step. Join professional associations like the Society of Manufacturing Engineers (SME) and attend industry conferences. Building connections can lead to job opportunities and insights into the field.

How long does it take to become a Manufacturing Engineer?

The path to becoming a Manufacturing Engineer starts with education. Most people begin with a bachelor's degree in engineering. This degree usually takes four years to complete. Some schools may offer specialized programs that can be shorter or longer.

After finishing a degree, gaining experience is key. Many new graduates take internships or entry-level positions. This helps them learn about real-world manufacturing processes. Professionals often spend a few years working in the field. They gain valuable skills and knowledge. With time, some may choose to pursue advanced degrees or certifications. This can lead to higher positions in the industry.

In total, becoming a skilled Manufacturing Engineer can take anywhere from four to eight years. This includes both education and experience. The exact time can vary based on individual circumstances and career goals.

Manufacturing Engineer Job Description Sample

We are seeking a highly skilled Manufacturing Engineer to join our dynamic team. This role will focus on optimizing production processes, improving product quality, and ensuring adherence to safety and quality standards.

Responsibilities:

- Develop and implement manufacturing processes to improve efficiency and reduce costs.

- Analyze production data to identify areas for improvement and implement solutions.

- Collaborate with cross-functional teams, including design, procurement, and quality assurance, to ensure seamless production.

- Maintain and troubleshoot manufacturing equipment to minimize downtime.

- Develop and enforce safety and quality standards to ensure compliance with regulations.

Qualifications

- Bachelor's degree in Manufacturing Engineering, Mechanical Engineering, or a related field.

- Proven experience as a Manufacturing Engineer or similar role.

- Strong understanding of manufacturing processes and equipment.

- Proficiency in CAD and CAM software.

- Excellent problem-solving and analytical skills.

Is becoming a Manufacturing Engineer a good career path?

A Manufacturing Engineer plays a key role in modern production. This career focuses on designing and improving manufacturing processes. It ensures products meet quality standards and are made efficiently. Companies value these engineers for their technical skills and problem-solving abilities. They work in various industries, from automotive to consumer goods.

Manufacturing Engineers often enjoy a mix of office and factory work. They use advanced tools and software to analyze and enhance production systems. This career can lead to roles with significant responsibility. It also offers opportunities for continuous learning and development. Engineers may specialize in areas like robotics or automation, expanding their skill set.

Like any career, manufacturing engineering has its pros and cons. Here are some to consider:

- Pros:

- Good job opportunities in many industries

- Potential for career advancement

- Opportunities to work on innovative projects

- Cons:

- May require long hours, especially during production runs

- Possible exposure to hazardous conditions in factories

- Demanding work that may involve problem-solving under pressure

What is the job outlook for a Manufacturing Engineer?

Job seekers looking to enter the field of manufacturing engineering will find promising opportunities ahead. The Bureau of Labor Statistics (BLS) reports an average of 24,100 job positions available each year. This steady demand makes it an attractive career path. Those who pursue this field can expect a stable and growing job market.

The BLS also forecasts an 11.2% increase in job openings for manufacturing engineers from 2022 to 2032. This growth reflects the industry's need for skilled professionals. Companies continue to innovate and improve their manufacturing processes. This trend creates a steady need for experienced manufacturing engineers who can drive these improvements.

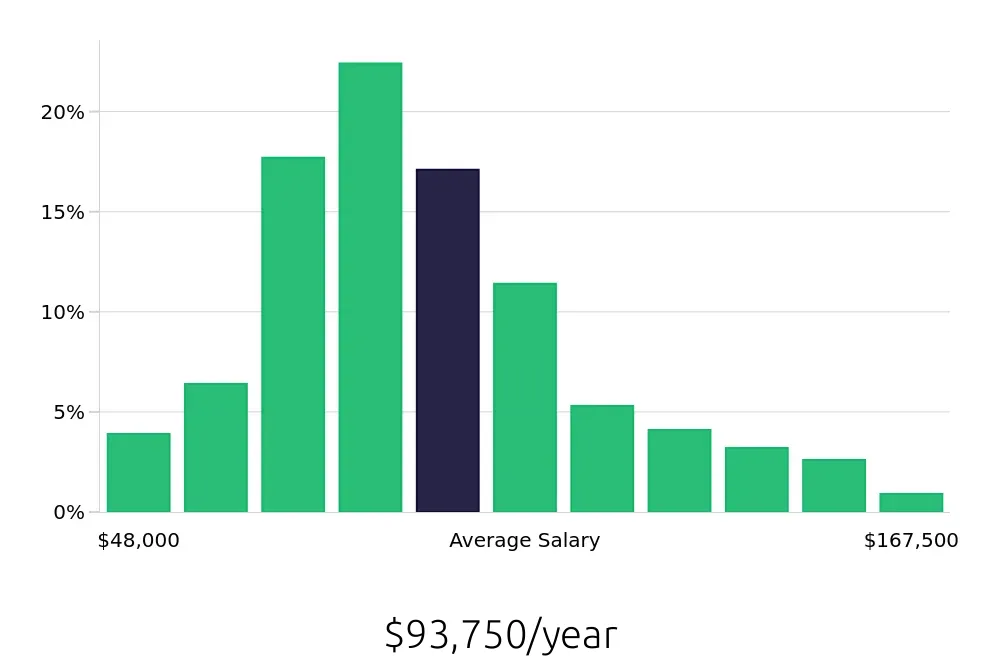

In terms of compensation, manufacturing engineers enjoy a competitive salary. The average national annual compensation stands at $103,510, according to the BLS. On an hourly basis, professionals in this role earn an average of $49.76. This compensation reflects the high level of skill and expertise required in the field. It also underscores the value that manufacturing engineers bring to their organizations.

Currently 1,540 Manufacturing Engineer job openings, nationwide.

Continue to Salaries for Manufacturing Engineer