Position

Overview

A Metal Finisher applies protective coatings to metal parts. This job involves preparing metal surfaces and applying paints, varnishes, and other finishes. A Metal Finisher ensures that the metal parts look good and last longer. This person uses various tools and chemicals to complete tasks.

Responsibilities of a Metal Finisher include cleaning metal parts to remove dirt and grease. They also prepare metal surfaces by sanding, buffing, and polishing. After preparing the surface, the Metal Finisher applies paint or other finishes. They use spray guns, rollers, or brushes for this task. Attention to detail is key, as the final appearance of the metal parts depends on their work. A Metal Finisher must follow safety guidelines to protect themselves and others from harmful chemicals.

Becoming a Metal Finisher can open doors to a rewarding career in the manufacturing and industrial sectors. This profession involves treating metal surfaces to improve their appearance and durability. It requires a mix of technical skills and attention to detail. Here is a clear path to start and succeed in this field.

First, gain a basic understanding of metals and their properties. This knowledge forms the foundation of the job. Next, find and complete a training program. Schools and trade organizations offer courses in metal finishing techniques. An apprenticeship can also provide hands-on experience. Each step builds the skills needed to excel in this role.

Metal finishing offers a rewarding career path with many opportunities. This field involves cleaning, polishing, and coating metals. Many people start their journey with a high school diploma. Training programs can last from a few months to two years. These programs teach skills like using chemicals and machinery.

Apprenticeships provide hands-on experience. They last about three to four years. During this time, workers earn while learning. Some metal finishers choose to earn a certification. Certifications can take a few months to complete. They show a worker’s skills and dedication. This can make them more attractive to employers. With the right training and experience, a career in metal finishing can be both stable and fulfilling.

The Metal Finisher is responsible for applying finishes to metal surfaces to enhance their appearance, durability, and protection. This role involves the use of various techniques and equipment to prepare, clean, and finish metal surfaces in accordance with project specifications.

Responsibilities:

Qualifications

A Metal Finisher works in various industries, from manufacturing to construction. They prepare metal surfaces for painting or coating. This job involves cleaning and sanding metal parts. Sometimes, they use chemicals to remove rust or other marks. Employers often need Metal Finishers to make sure the final product looks good and lasts long.

Being a Metal Finisher has its own set of advantages and challenges. Let's look at some of them:

Job seekers interested in becoming a metal finisher will find a stable yet slightly shrinking job market. The Bureau of Labor Statistics (BLS) reports an average of 26,100 job positions per year. However, job openings are expected to decrease by 10.8% from 2022 to 2032. This slight decline suggests the need for careful consideration and continuous skill development in this field. Job seekers should focus on acquiring new skills to remain competitive.

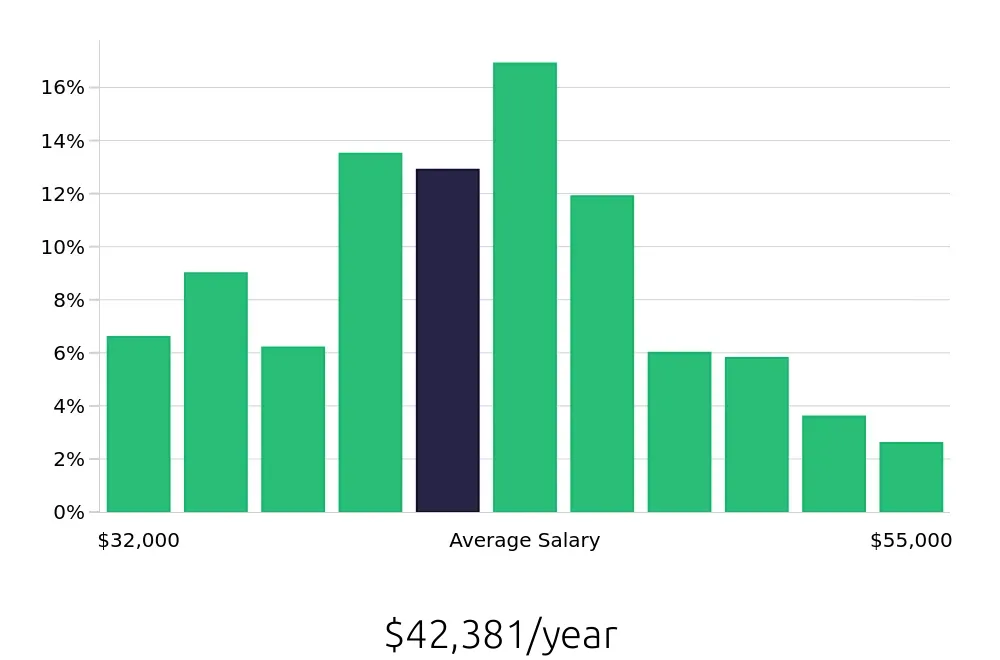

Despite the projected decrease in job openings, the metal finishing industry offers a competitive average annual compensation of $44,950. This figure makes the role attractive to those looking for stable earnings. Additionally, the hourly rate of $21.61 provides a good balance between time and compensation. These figures reflect a reasonable income for those entering or continuing in this profession.

Given the stable demand and solid compensation, metal finishing remains a viable career path. Job seekers should consider this field if they are interested in a role that requires technical skills and attention to detail. Staying informed about industry trends and continuously improving skills can help navigate the changes in the job market.