What does a Metrology Technician do?

A Metrology Technician plays a crucial role in ensuring precision and accuracy in manufacturing and quality control processes. This professional operates specialized equipment to measure and inspect parts and products. They use tools like calipers, micrometers, and coordinate measuring machines. Their work involves interpreting technical drawings and specifications. This helps in determining if a product meets the required standards. Accuracy and attention to detail are key to their job. Metrology Technicians work closely with engineers and quality control teams. They ensure that manufacturing processes are consistent and reliable.

In their daily tasks, a Metrology Technician collects data from various measurements. They analyze this data to identify any deviations from the set standards. If discrepancies arise, they report them and suggest corrective actions. This helps in maintaining high-quality output. This technician also calibrates and maintains measurement equipment. They ensure that all tools are functioning correctly. Proper equipment maintenance is essential for reliable results. This role requires strong analytical skills and a commitment to precision. Metrology Technicians contribute to the overall efficiency and effectiveness of production processes.

How to become a Metrology Technician?

Becoming a metrology technician involves specific steps that ensure a solid foundation in the field. This career path requires precision and attention to detail, making it ideal for those who enjoy working with technical instruments and measurements. Here is an outline of the process to guide you through becoming a metrology technician.

To embark on this career, start by acquiring the necessary education. Most employers look for candidates with at least an associate's degree in a related field. Some may require a bachelor's degree. Programs often include courses in mathematics, physics, and engineering. Gaining hands-on experience through internships or apprenticeships can also be very beneficial.

Next, develop a set of essential skills. These include a strong understanding of measurement principles, proficiency with various instruments, and the ability to analyze data accurately. Familiarity with computer software used in metrology is also important. Building these skills can be achieved through formal training, on-the-job experience, or specialized certifications.

- Obtain the required education: Start with an associate's or bachelor's degree in metrology or a related field.

- Learn necessary skills: Develop proficiency in measurement principles, instrument use, and data analysis.

- Gain experience: Work through internships or apprenticeships to build practical knowledge.

- Get certified: Consider obtaining certifications to enhance credentials and job prospects.

- Apply for jobs: Look for positions in industries that require precise measurements, such as manufacturing or aerospace.

How long does it take to become a Metrology Technician?

Choosing a career as a Metrology Technician offers a stable and rewarding path. This role involves precise measurement work and quality control in industries. The time to start working as a Metrology Technician varies based on education and experience.

Typically, a high school diploma or equivalent is the starting point. Many employers prefer candidates with some post-secondary education. Programs range from certificates to associate degrees. These can take anywhere from one to two years to complete. Some choose to gain experience through on-the-job training, which can also lead to this career path. Experience in related fields, such as engineering or machining, can help in gaining employment faster. Certification from recognized bodies can enhance job prospects and may be required in certain roles. This certification process usually takes an additional six months to a year, depending on the chosen course.

Metrology Technician Job Description Sample

As a Metrology Technician, you will be responsible for ensuring the precision and accuracy of measurements and calibrations across various manufacturing and quality assurance processes. This role involves operating and maintaining metrology instruments, conducting inspections, and ensuring all equipment is compliant with industry standards.

Responsibilities:

- Operate and calibrate precision measuring instruments, ensuring all tools are accurate and functioning properly.

- Perform routine inspections and tests on products and components to ensure compliance with specifications and standards.

- Document and report findings, ensuring all data is accurate and detailed.

- Collaborate with engineering and quality assurance teams to troubleshoot measurement-related issues.

- Maintain a clean and organized metrology laboratory, ensuring all instruments are stored and maintained correctly.

Qualifications

- Associate or Bachelor’s degree in Metrology, Engineering, Physics, or a related field.

- Certification from a recognized metrology institution is highly desirable.

- Minimum of 2 years of experience in a metrology or quality assurance role.

- Strong understanding of measurement principles and techniques.

- Excellent attention to detail and precision in all tasks.

Is becoming a Metrology Technician a good career path?

A Metrology Technician plays a key role in ensuring the precision of manufactured goods. This career blends science and technology. Metrology Technicians measure and analyze different aspects of materials and products. They use high-tech tools and equipment. They work in various industries, including automotive, aerospace, and electronics.

Becoming a Metrology Technician offers both advantages and challenges. Let’s explore some pros and cons to consider.

Pros of Being a Metrology Technician:

- Job stability: High demand in manufacturing and technology sectors.

- Good pay: Competitive salaries, often with benefits.

- Skill development: Learn to use advanced measuring tools and software.

- Variety of settings: Opportunities in labs, manufacturing plants, and quality control.

Cons of Being a Metrology Technician:

- Technical skills required: Need to understand complex equipment and software.

- Attention to detail: Must be very precise, as errors can be costly.

- Physical demands: May involve standing for long periods or working in uncomfortable conditions.

- Limited interaction: May spend a lot of time working alone or with small teams.

What is the job outlook for a Metrology Technician?

The job outlook for Metrology Technicians shows a steady demand in the market. Each year, about 22,300 positions become available, according to the Bureau of Labor Statistics (BLS). This consistent demand means job seekers can find opportunities throughout the year. While the percent change from 2022 to 2032 is a slight decline of 0.2%, the overall trend remains positive. This slight decrease does not signal a poor outlook but suggests a stable market.

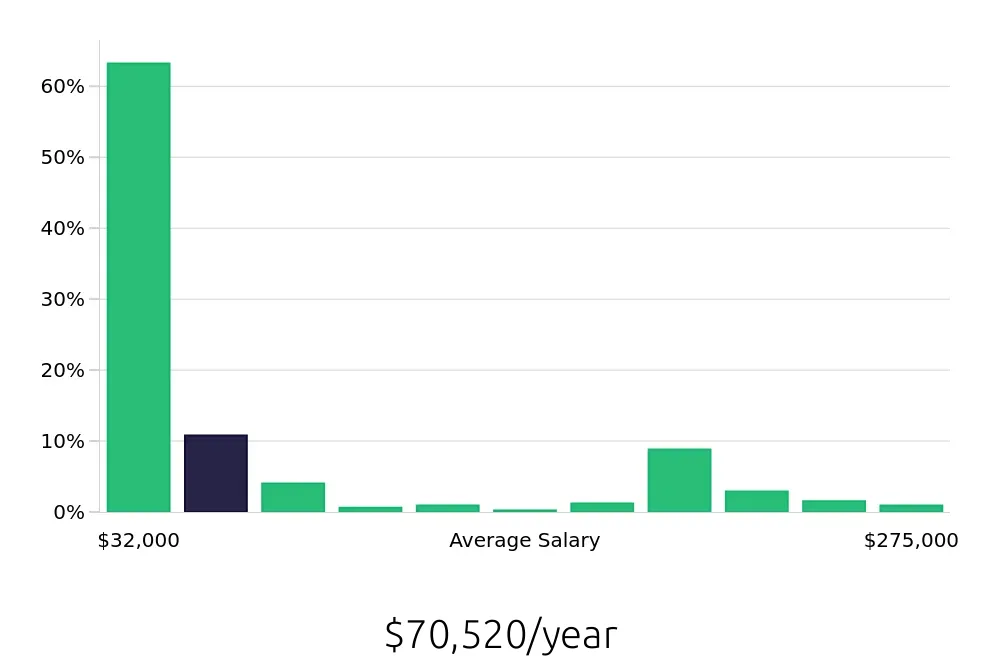

Metrology Technicians enjoy a competitive average national annual compensation of $65,100. This salary reflects the value employers place on skilled professionals in this field. Hourly compensation averages $31.3, offering good pay for the work done. This attractive salary makes the role appealing to many job seekers. The good income potential is a strong reason to consider this career path.

When looking for Metrology Technician positions, candidates can expect a market with consistent opportunities. The slight projected decline in job openings does not overshadow the good pay and steady demand. Job seekers can confidently explore this field, knowing there are plenty of roles available. The combination of a stable job outlook and good compensation makes this career path a solid choice for professionals.

Currently 167 Metrology Technician job openings, nationwide.

Continue to Salaries for Metrology Technician