What does a Mold Technician do?

A Mold Technician works in a manufacturing environment. They are responsible for setting up and operating machinery to make molds. These molds are used to produce parts or items in various industries, such as automotive or consumer goods. A Mold Technician ensures the equipment functions correctly and safely. They also make adjustments to molds to meet specific production needs.

Key tasks include inspecting molds for wear and damage, cleaning and maintaining equipment, and recording production data. This role requires attention to detail and a strong understanding of machinery. A Mold Technician must follow precise instructions and maintain a clean work area. They must also be able to troubleshoot problems that arise with the molds or machinery. This job involves both manual and technical skills, making it ideal for those who enjoy hands-on work and problem-solving.

How to become a Mold Technician?

Becoming a Mold Technician requires a clear path and dedication to learning. This career is ideal for those interested in working with manufacturing and production processes. It involves creating molds for making products in various materials, such as metal or plastic. The job is both creative and technical, making it appealing to a wide range of skilled workers.

Below are five steps to guide someone in becoming a Mold Technician:

- Earn a high school diploma: The first step is to complete high school. This provides a strong foundation in subjects like math and science, which are important for this career.

- Get a post-secondary education: Many Mold Technicians attend a trade school or community college. Programs typically last 1-2 years and cover topics like tool and die making.

- Gain experience: Working under a skilled technician helps. This can be through an apprenticeship or entry-level jobs in a factory or mold-making company.

- Learn specialized skills: Familiarity with CAD (Computer-Aided Design) software and precision measuring tools is crucial. These skills help in creating detailed mold designs and ensuring accuracy.

- Obtain certification: While not always necessary, certification from organizations like the National Tooling and Machining Association (NTMA) can enhance job prospects and credibility.

How long does it take to become a Mold Technician?

The journey to becoming a Mold Technician often involves a blend of formal education and hands-on experience. Typically, it takes about two to four years to complete the necessary training and gain the required skills. Many individuals start by obtaining a high school diploma or a GED. After that, they pursue a certificate or an associate's degree in fields like manufacturing technology or industrial engineering. Some programs may offer specialized courses in mold-making and mold repair.

Practical experience enhances the learning process. Many programs include internships or apprenticeships. These opportunities allow students to work under experienced professionals. They learn to use tools and equipment while applying the knowledge gained in the classroom. Graduates with the right qualifications can expect to find entry-level positions. With time and experience, Mold Technicians can advance to higher-paying roles and greater responsibilities.

Mold Technician Job Description Sample

We are seeking a skilled Mold Technician to join our team. The ideal candidate will be responsible for the design, construction, and maintenance of molds used in manufacturing processes. This role requires a strong attention to detail, technical knowledge, and the ability to work with various materials and machinery.

Responsibilities:

- Design, construct, and maintain molds according to engineering specifications.

- Operate and maintain molding machines and related equipment.

- Inspect molds and correct any deficiencies to ensure high-quality production.

- Collaborate with engineering and production teams to optimize mold performance.

- Create and maintain detailed records of mold specifications and modifications.

Qualifications

- High school diploma or equivalent; technical training or degree in mold making or related field is preferred.

- Proven experience as a Mold Technician or similar role.

- Strong understanding of mold design, construction, and maintenance.

- Proficiency in using CAD software and other design tools.

- Excellent problem-solving and analytical skills.

Is becoming a Mold Technician a good career path?

A Mold Technician works with tools to create molds for manufacturing. They follow instructions to shape metal, plastic, or rubber. They measure and mark materials to fit the design. Technicians must follow safety rules to protect themselves. This job needs focus and good attention to detail.

Working as a Mold Technician offers several benefits. First, the work is hands-on and practical. Technicians use their skills every day. They learn new techniques and tools. Mold Technicians often work in clean environments. They might also enjoy steady employment, as molds are needed for many products. However, this career has some challenges. Technicians may work with heavy or sharp tools. They might deal with uncomfortable conditions, like loud noises or hot areas. The job can be repetitive, which may not suit everyone.

Here are some pros and cons to consider:

- Pros:

- Hands-on work

- Steady employment

- Opportunities to learn

- Cons:

- Potentially hazardous tools

- Possible exposure to uncomfortable conditions

- Repetitive tasks

What is the job outlook for a Mold Technician?

Mold technicians play a crucial role in various industries, from automotive to manufacturing. The job outlook for mold technicians reflects steady demand within these sectors. The Bureau of Labor Statistics (BLS) reports approximately 14,600 new job positions each year, showcasing opportunities for those entering the field. Despite a forecasted decrease of 5% in job openings from 2022 to 2032, the overall market remains stable, emphasizing the importance of specialized skills.

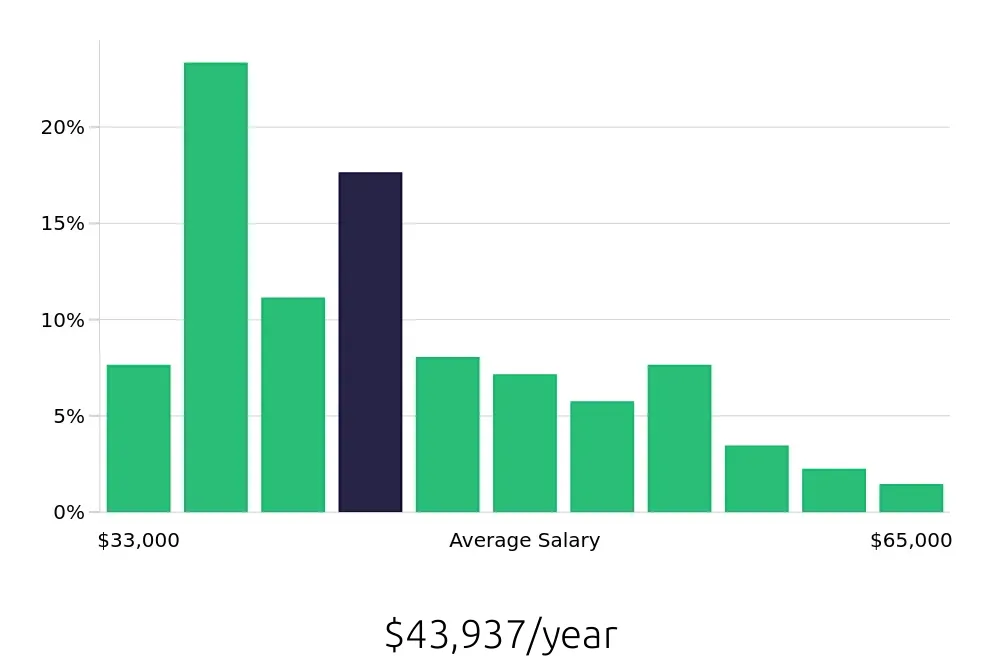

For those considering a career as a mold technician, understanding the financial benefits is essential. The BLS indicates an average national annual salary of $42,270, offering a decent income. Additionally, the average hourly compensation stands at $20.32, reflecting fair remuneration for the expertise required. This compensation aligns with the industry's demand for skilled professionals, making it a lucrative field for job seekers.

Job seekers interested in mold technology can look forward to a stable career with competitive pay. While the number of new positions may decrease slightly, the core demand for skilled mold technicians persists. This balance ensures that experienced professionals will continue to find employment and may even see opportunities for career advancement. Therefore, investing time in acquiring the necessary skills and certifications can lead to a rewarding career in this field.

Currently 54 Mold Technician job openings, nationwide.

Continue to Salaries for Mold Technician