What does a Molding Operator do?

A Molding Operator plays a crucial role in manufacturing and production environments. This person operates machinery to create products from materials like plastic, rubber, or metal. They monitor equipment to ensure smooth operation and handle various tasks to meet production targets.

Responsibilities include setting up the machinery, checking materials, and operating controls. A Molding Operator must follow safety protocols and maintain equipment. They also inspect finished products for quality. This role demands attention to detail and the ability to work efficiently. Attention to detail helps ensure products meet standards. It also ensures machinery runs smoothly.

How to become a Molding Operator?

Interested in becoming a Molding Operator? This role is important in manufacturing and involves shaping materials using molds. Here is a clear guide to help start this career.

First, gaining the necessary education and skills is essential. Molding operators typically need a high school diploma or equivalent. Some employers may prefer candidates who have completed vocational training or apprenticeship programs related to manufacturing or machinery operation.

Next, consider gaining experience in a related field. Entry-level positions in manufacturing or factory work can provide valuable hands-on experience. This experience helps in understanding machinery and production processes. Look for opportunities that offer training on the specific equipment used in molding operations.

- Obtain a high school diploma or equivalent.

- Complete vocational training or apprenticeship programs in manufacturing.

- Gain experience in a related field such as manufacturing or factory work.

- Learn to operate specific molding equipment.

- Seek certification or additional training as needed.

After gaining experience, focus on learning to operate molding equipment. Molding operators must understand how to set up and run machines correctly. Some companies offer on-the-job training for new employees. Others may require or recommend specific certifications.

Finally, consider seeking additional training or certification. Many employers value candidates with formal training in machine operation or industrial technology. Certifications from organizations such as the National Center for Construction Education and Research (NCCER) can enhance job prospects. Continuous learning and staying updated on industry trends are also important for career growth.

How long does it take to become a Molding Operator?

Interest in becoming a Molding Operator can vary greatly, depending on the path chosen. Most Molding Operators complete a short-term training program. These programs often take a few weeks to several months. They cover essential skills and safety protocols.

After completing the training, many Molding Operators start with entry-level positions. With experience and dedication, it is possible to advance to more skilled roles. Gaining more experience can lead to higher pay and better job opportunities. Employers value workers who show a commitment to learning and improving their skills. A Molding Operator can start their career in a relatively short time and continue to grow throughout their professional life.

Molding Operator Job Description Sample

A Molding Operator is responsible for operating machinery to produce and mold plastic, rubber, or metal parts. This role involves setting up and maintaining machinery, monitoring production processes, and ensuring high-quality output.

Responsibilities:

- Operate and monitor machinery to produce plastic, rubber, or metal parts.

- Set up and adjust equipment according to production specifications.

- Monitor production processes to ensure quality and efficiency.

- Inspect finished products for defects and take corrective actions as necessary.

- Maintain a clean and safe working environment.

Qualifications

- High school diploma or equivalent required; technical or vocational training preferred.

- Previous experience as a Molding Operator or in a similar role.

- Knowledge of machinery operation and maintenance principles.

- Ability to read and interpret blueprints and technical documents.

- Strong attention to detail and quality control skills.

Is becoming a Molding Operator a good career path?

A Molding Operator plays a vital role in manufacturing, working with machines to create various products. This role requires attention to detail and the ability to work in a fast-paced environment. Companies often look for operators who can handle repetitive tasks and ensure high-quality output. The work environment can vary, from clean factory settings to more industrial and noisy conditions.

Working as a Molding Operator has its benefits and challenges. Consider these pros and cons before choosing this career path. On the positive side, jobs are often available in many industries, providing good job security. Training is usually provided, making it accessible even for those without a college degree. Pay rates can be competitive, with opportunities for overtime and shift differentials. However, the job can be physically demanding, with potential for repetitive strain injuries. Shift work might also disrupt personal schedules, making it hard to balance work and life. The repetitive nature of the work could lead to monotony, though automation and technology are helping to change this.

Here are some more pros and cons to think about:

- Pros:

- Job security with many opportunities available.

- Training provided, accessible with or without a college degree.

- Competitive pay rates and chances for overtime.

- Cons:

- Physical demands can lead to repetitive strain injuries.

- Shift work can disrupt personal schedules.

- Repetitive nature of the job might cause monotony.

What is the job outlook for a Molding Operator?

The job outlook for Molding Operators shows a steady demand for skilled workers. The Bureau of Labor Statistics (BLS) reports around 78,100 job openings annually. This means there are many opportunities for those looking to enter this field. While job openings are expected to decrease by 3.5% from 2022 to 2032, Molding Operator roles remain stable in manufacturing. This stability offers a reliable career path for job seekers.

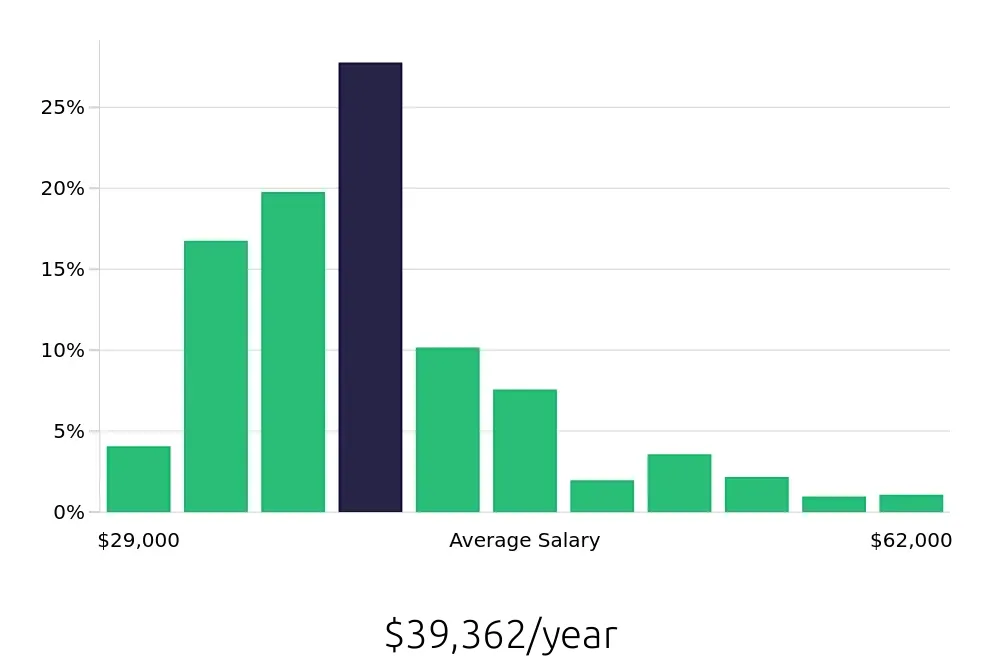

For those interested in this career, the BLS reports a solid average national annual compensation of $42,360. This pay rate reflects the value of the skills and experience required in this role. Molding Operators use their expertise to ensure high-quality production in various industries. This compensation level is competitive, making it an attractive choice for many job seekers. The BLS also reports an average hourly wage of $20.36, which can be rewarding for those who excel in their work.

Job seekers should also consider the diverse opportunities available within this role. Molding Operators can work in a variety of settings, from automotive manufacturing to consumer goods production. This versatility allows for flexibility in career choices and the potential for growth. Those interested in a stable career with good earning potential should look into Molding Operator positions. The consistent demand and respectable pay make this a worthwhile field to explore.

Currently 87 Molding Operator job openings, nationwide.

Continue to Salaries for Molding Operator