What does a NDT Inspector do?

An NDT Inspector plays a crucial role in ensuring the safety and integrity of various materials and structures. This professional uses non-destructive testing methods to examine materials without causing damage. They inspect welds, pipelines, and other components to detect flaws or defects. The job requires a keen eye for detail and a strong understanding of the materials being tested. NDT Inspectors work in many industries, including construction, manufacturing, and aerospace.

The responsibilities of an NDT Inspector include preparing equipment for testing, conducting tests, and analyzing results. They must follow strict safety protocols and maintain accurate records of their findings. NDT Inspectors often work in teams and communicate their results to engineers and supervisors. This role demands a high level of accuracy and reliability, as the results of their tests can impact safety and quality. NDT Inspectors must stay updated with the latest testing technologies and techniques to perform their duties effectively.

How to become a NDT Inspector?

Becoming a Non-Destructive Testing (NDT) Inspector can open doors to a rewarding career in various industries. This role involves using advanced techniques to test materials and components without damaging them. It requires a mix of technical skills and attention to detail. Here are the steps to start this career path.

First, gaining the right education is crucial. Most employers look for candidates with a high school diploma or equivalent. Some may prefer or require a post-secondary certificate or associate degree in NDT or a related field. This education provides the foundational knowledge needed to understand the principles and methods of NDT.

- Get the necessary education: Obtain a high school diploma or GED. Consider furthering education with a certificate or degree in NDT.

- Gain relevant experience: Look for internships or entry-level positions in industries that use NDT. This hands-on experience is valuable and can lead to job opportunities.

- Get certified: Certification is often required. Organizations like the American Society for Nondestructive Testing (ASNT) offer various certification levels. Achieving certification can enhance job prospects and credibility.

- Develop technical skills: Learn to use NDT equipment and techniques. This includes understanding how to interpret test results and identify defects. Continuous training and skill development are important in this field.

- Build a professional network: Connect with other NDT professionals. Attend industry events, join professional associations, and participate in online forums. Networking can lead to job leads and career advancement.

How long does it take to become a NDT Inspector?

The journey to becoming a Non-Destructive Testing (NDT) Inspector involves several steps. First, an individual needs to complete a training program. This program teaches the skills needed to inspect materials and structures. Many programs last from a few weeks to several months. Some offer certification upon completion.

After training, gaining experience is key. Many inspectors start as apprentices. They work under experienced inspectors to learn on the job. This hands-on experience is crucial. It helps inspectors understand real-world applications of NDT methods. Over time, inspectors build their skills and confidence. They can then take exams to become certified. Certification shows a professional level of skill and knowledge. It opens up more job opportunities and higher pay.

NDT Inspector Job Description Sample

We are seeking a skilled NDT Inspector to join our team. The NDT Inspector will be responsible for performing non-destructive testing (NDT) on various materials and components to ensure they meet quality standards and specifications. This role requires a keen eye for detail, strong technical skills, and the ability to work in a fast-paced environment.

Responsibilities:

- Perform non-destructive testing (NDT) on materials and components using various methods such as ultrasonic, radiographic, magnetic particle, dye penetrant, and eddy current testing.

- Interpret test results and prepare detailed reports, highlighting any defects or areas of concern.

- Ensure all testing is conducted in accordance with industry standards and company procedures.

- Collaborate with engineering and production teams to ensure testing schedules are met and any issues are addressed promptly.

- Maintain and calibrate NDT equipment to ensure accuracy and reliability of test results.

Qualifications

- Bachelor’s degree in Engineering, Materials Science, or a related field.

- Certification in a recognized NDT method (e.g., ASNT, NDE, or equivalent).

- Minimum of 3 years of experience in NDT inspection.

- Strong understanding of materials science and engineering principles.

- Excellent analytical and problem-solving skills.

Is becoming a NDT Inspector a good career path?

Working as an NDT Inspector involves using advanced technology to check materials and structures for flaws. This job plays a key role in ensuring safety and quality in many industries. NDT Inspectors use methods like ultrasound, magnetic particles, and dye penetrants. They work in places like construction sites, factories, and oil rigs. This career offers a mix of hands-on work and technical skills.

Choosing this career path has its own set of advantages and disadvantages. On the positive side, NDT Inspectors often enjoy good job stability and competitive pay. They also get to work on a variety of projects, which keeps the job interesting. However, the job can be physically demanding and may require long hours. Inspectors also need to stay updated with the latest technology and safety standards. Balancing these pros and cons can help job seekers decide if this career is right for them.

Here are some key points to consider:

- Pros:

- Good job stability

- Competitive pay

- Variety of projects

- Cons:

- Physically demanding

- Long hours

- Need for continuous learning

What is the job outlook for a NDT Inspector?

The job outlook for NDT Inspectors is promising for those seeking a stable career in the field. According to the Bureau of Labor Statistics (BLS), there are approximately 37,800 job positions available each year. This consistent number of openings indicates a steady demand for skilled professionals in this role. Job seekers can expect a reliable job market with numerous opportunities to explore.

Looking ahead, the job outlook for NDT Inspectors remains positive. The BLS projects a 1.8% increase in job openings from 2022 to 2032. This growth suggests that the demand for qualified NDT Inspectors will continue to rise. Job seekers can anticipate a favorable environment for career advancement and job security in this field. With the industry's steady growth, there are ample opportunities for those who are well-trained and dedicated to this profession.

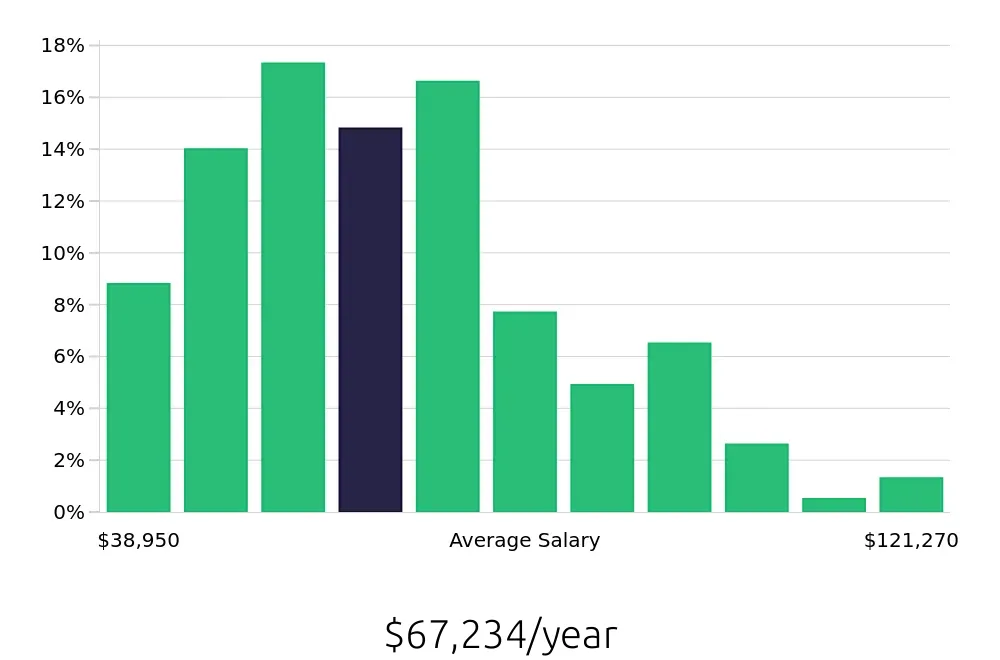

NDT Inspectors can also look forward to a competitive salary. The BLS reports an average national annual compensation of $70,080. This figure reflects the value placed on the skills and expertise of NDT Inspectors. Additionally, the average national hourly compensation stands at $33.69, highlighting the rewarding nature of this career. Job seekers will find that this profession offers not only job stability but also financial benefits that can support a comfortable lifestyle.

Currently 128 NDT Inspector job openings, nationwide.

Continue to Salaries for NDT Inspector