What does a Plater do?

A Plater works in the production and manufacturing industry. This person assembles metal plates to create structures or items. They use welding, cutting, and bending techniques to shape metal. Platers ensure all pieces fit together correctly. They often work with blueprints or sketches to guide their work.

Plater tasks include measuring and marking metal sheets. They use tools like saws and grinders to cut metal to size. Platers then weld pieces together. They must check for errors and make sure everything fits. This job demands attention to detail and physical strength. Platers often work in factories or workshops. This role is essential for building many everyday items.

How to become a Plater?

Becoming a plater involves learning a unique set of skills to create and finish metal surfaces. This career can be very rewarding for those interested in working with metals and improving their technical abilities. Below are five steps to guide anyone interested in this career path.

First, one should start with education. Most platers begin with a high school diploma or equivalent. Taking classes in metalworking or vocational training can be very beneficial. Look for local trade schools or community colleges that offer these courses. Second, gaining hands-on experience is crucial. Seek out internships or apprenticeships with experienced platers. This practical experience is invaluable and helps to build a strong portfolio.

- Learn the basics of metalworking

- Complete formal education or training

- Gain hands-on experience through apprenticeships

- Get certified if needed

- Build a professional network

Third, getting certified can improve job prospects. Certifications from organizations like the National Institute for Metalworking Skills (NIMS) can set a professional apart. Fourth, building a professional network is important. Join industry groups, attend workshops, and connect with other professionals. This network can lead to job opportunities and valuable advice. Lastly, staying updated with the latest techniques and tools is essential. The metalworking industry is always evolving, and continuous learning will help to stay competitive.

How long does it take to become a Plater?

Interested in becoming a Plater? This role involves shaping and finishing metal surfaces. The time needed to master this trade varies based on experience and dedication. Many start with an apprenticeship program that lasts 3 to 4 years. During this period, Platers learn the necessary skills through on-the-job training and classroom instruction.

Once the apprenticeship concludes, gaining experience becomes crucial. Entry-level Platers may work under a skilled mentor to refine their techniques. Over time, a Plater’s proficiency grows, leading to greater job opportunities and responsibilities. Most find that they reach full competency within 5 to 7 years of starting their journey. Consistent practice and learning from experienced Platers play a key role in this process.

Plater Job Description Sample

We are seeking a skilled Plater to join our team. The Plater will be responsible for applying metal coatings to various surfaces to enhance durability, appearance, and functionality. This role requires precision, attention to detail, and adherence to safety protocols.

Responsibilities:

- Apply metal coatings to surfaces using various techniques such as electroplating, hot dip plating, or mechanical plating.

- Prepare surfaces by cleaning, degreasing, and roughening to ensure proper adhesion of coatings.

- Monitor and adjust plating equipment and solutions to maintain optimal conditions for coating application.

- Inspect plated surfaces for defects, imperfections, and adherence, and take corrective actions as needed.

- Maintain accurate records of plating processes, materials used, and product specifications.

Qualifications

- High school diploma or equivalent; technical training or certification in metal finishing or a related field is a plus.

- Proven experience as a Plater or in a similar role, with a strong understanding of metal coating processes and techniques.

- Proficiency in operating plating equipment and handling chemicals safely.

- Attention to detail and the ability to produce consistent, high-quality results.

- Strong problem-solving skills and the ability to work independently with minimal supervision.

Is becoming a Plater a good career path?

Plater work involves using metal plates to cover holes and damage in cars, ships, or other structures. This role requires skill with welding tools and an eye for detail. Platers can find jobs in various industries, including automotive repair shops and marine repair facilities. The career offers a mix of physical labor and technical expertise.

Choosing a path as a plater has both advantages and challenges. Here are some pros and cons to consider:

- Pros:

- Stable Employment: There is consistent demand for skilled platers.

- Good Pay: Platers often earn competitive wages.

- Skill Development: The job offers opportunities to learn and improve welding skills.

- Variety of Work: Platers may work on different types of projects, from vehicles to boats.

- Cons:

- Physical Demands: The job involves standing for long periods and handling heavy materials.

- Safety Risks: Working with welding equipment can pose health hazards.

- Seasonal Work: Some platers may face job shortages during off-seasons.

- Limited Mobility: Platers often need to stay in one area to find consistent work.

What is the job outlook for a Plater?

For job seekers interested in the field of plating, there is a steady demand for skilled workers. The Bureau of Labor Statistics (BLS) reports an average of 6,900 job positions available each year. While the outlook shows a slight decline of 8.9% in job openings from 2022 to 2032, this trend is common across various industries. Job seekers should stay focused on acquiring the necessary skills to remain competitive in this field.

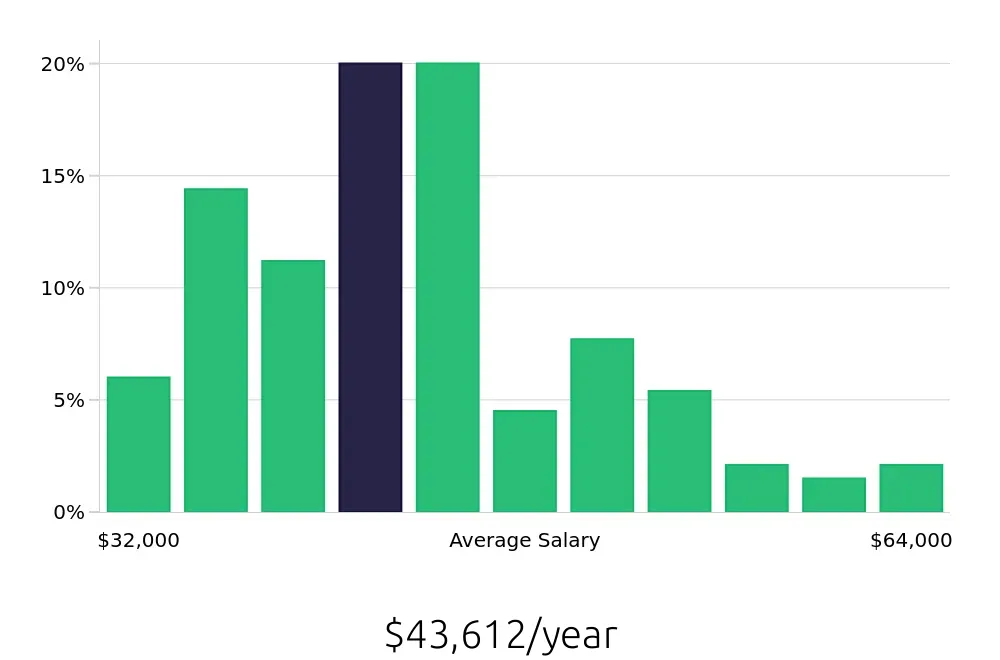

The average national annual compensation for platers stands at $45,800, according to the BLS. This figure indicates a stable earning potential for those who master the trade. In addition to the annual salary, the average hourly compensation is $22.02, offering good pay for both full-time and part-time positions. These numbers reflect the value employers place on skilled plating professionals.

Job seekers should note that while the number of positions might decrease slightly over the next decade, the role of platers remains vital in various industries. Continuous learning and skill enhancement can help professionals navigate any changes in the job market. Keeping up-to-date with industry trends and technologies will provide a competitive edge in securing employment.

Currently 37 Plater job openings, nationwide.

Continue to Salaries for Plater