What does a Polisher do?

A Polisher works to enhance the visual appeal and functionality of various materials. This role involves sanding, buffing, and finishing surfaces to ensure they meet high-quality standards. Polishers often work with metals, wood, and other materials in industries such as automotive, furniture, and manufacturing.

Daily tasks for a Polisher include assessing the surface condition, selecting appropriate tools and materials, and applying techniques to achieve a smooth, shiny finish. This position requires attention to detail and steady hands to avoid damaging the surface. Polishers need to follow safety protocols to protect themselves and the environment. This role offers an opportunity to work in a variety of settings, from workshops to production floors, and to produce items that people use every day.

How to become a Polisher?

Becoming a polisher can lead to a rewarding career in various industries. Polishers are professionals who specialize in refining and enhancing the quality of materials and surfaces. This involves the use of specialized tools and techniques to achieve a smooth and shiny finish. The role can be found in sectors such as manufacturing, automotive, jewelry, and more.

Polishers must possess a keen eye for detail and strong manual dexterity. They often work with various materials, including metals, glass, and stone. Polishers ensure that the final product meets the highest standards of quality and aesthetics. This can significantly impact the reputation of the company they work for. Understanding the steps to become a polisher can help guide your career path.

- Gain Education and Training: Start with a high school diploma or GED. Consider taking vocational courses in metalworking, gemology, or a related field. Apprenticeships can provide hands-on experience.

- Develop Necessary Skills: Polishers need strong attention to detail, manual dexterity, and the ability to work with precision tools. Practice using polishing machines, sanding tools, and buffing equipment.

- Obtain Certification: Some employers may prefer or require certification in a specific area. Certifications from professional organizations can be beneficial. They demonstrate your commitment to the profession.

- Seek Employment: Look for job openings in industries that require polishers. Tailor your resume to highlight your skills and experience. Networking with industry professionals can open doors to job opportunities.

- Continue Professional Development: Stay updated with the latest techniques and tools in the polishing industry. Attend workshops, seminars, and industry events. Continuous learning can lead to career advancement and better job prospects.

How long does it take to become a Polisher?

A Polisher works to make surfaces shine and smooth. This job requires special skills and training. The path to becoming a Polisher varies based on the specific field. In general, it can take anywhere from a few weeks to several years.

For those entering the field, training programs can last from a few weeks to a few months. These programs teach basic skills and techniques. Some programs offer certification upon completion. A certificate can make a candidate more attractive to employers. Many Polishers start as apprentices. They work under experienced professionals. On-the-job training helps them gain practical experience. This hands-on learning often takes one to two years. Experienced Polishers may find opportunities for advancement. Specializing in certain areas can lead to higher positions. This can take several more years.

Polisher Job Description Sample

We are seeking a skilled Polisher to join our team. The ideal candidate will have a keen eye for detail and a strong commitment to delivering high-quality polished surfaces. This role requires expertise in various polishing techniques and the ability to work with different materials.

Responsibilities:

- Perform surface polishing on various materials including metal, wood, and plastic.

- Inspect and assess the condition of surfaces to determine the appropriate polishing technique.

- Operate and maintain polishing equipment to ensure optimal performance.

- Follow safety protocols and maintain a clean and organized work area.

- Communicate with team members and supervisors to ensure project timelines are met.

Qualifications

- Proven experience as a Polisher or similar role.

- Proficiency in using various polishing tools and equipment.

- Strong understanding of different polishing techniques and their applications.

- Excellent attention to detail and commitment to quality.

- Ability to work independently and as part of a team.

Is becoming a Polisher a good career path?

A Polisher works in the field of manufacturing or construction. They use machines to smooth and shine surfaces. This role often requires attention to detail and a steady hand. Polishers can work with metal, stone, or wood. The job demands a good understanding of materials and tools.

This career offers several benefits. Polishers can find work in many industries. They might polish parts for cars, jewelry, or buildings. The job can lead to steady employment. Companies always need surfaces that look good. However, the work can be repetitive. Polishers spend a lot of time on the same tasks. This can lead to physical strain over time. It's important to know these pros and cons before starting this job path.

Here are some pros and cons to consider:

- Pros:

- Steady job opportunities in many industries.

- Opportunity to work with different materials.

- Skills developed can lead to career advancement.

- Cons:

- Repetitive tasks can lead to physical strain.

- Limited opportunities for career change within the role.

- Exposure to chemicals and dust in some environments.

What is the job outlook for a Polisher?

Becoming a polisher offers a stable career path in a specialized field. On average, the Bureau of Labor Statistics (BLS) reports 26,100 job positions available per year. This consistent demand reflects the ongoing need for skilled professionals in this sector. Job seekers can find a steady stream of opportunities, making it a reliable choice for those seeking employment stability.

While the outlook for polisher positions is promising, it is important to note the projected job openings percent change from 2022 to 2032, which is a decrease of 10.8%, according to the BLS. This change indicates a slight decline in the number of available positions. However, the existing demand ensures that experienced polishers will continue to find suitable job openings. It’s a good idea for job seekers to stay updated on industry trends and continuously enhance their skills to remain competitive.

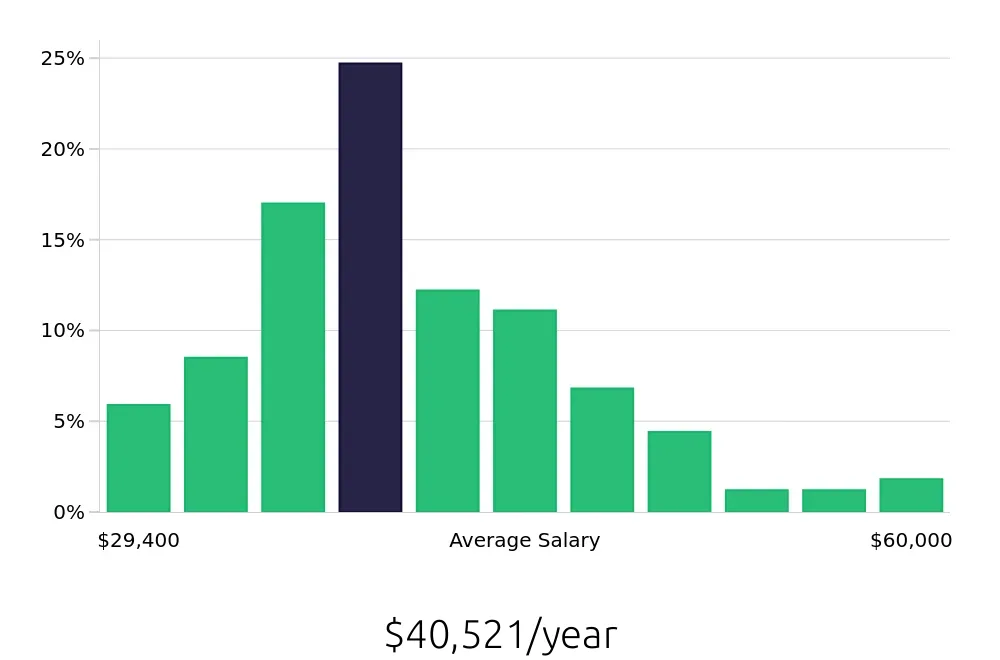

The financial benefits of a career as a polisher are also noteworthy. The BLS reports an average national annual compensation of $44,950, with an hourly rate of $21.61. This compensation reflects the value placed on skilled polishers in the industry. Job seekers can expect a rewarding salary that aligns with their expertise and experience. With the right qualifications and dedication, a career as a polisher can provide both job security and financial stability.

Currently 63 Polisher job openings, nationwide.

Continue to Salaries for Polisher