What does a Rebar Fabricator do?

A Rebar Fabricator assembles, cuts, bends, and ties rebar for use in construction projects. This role involves understanding blueprints and construction plans to ensure accurate fabrication. The fabricator works with various tools to measure, cut, and manipulate steel bars. Precision and attention to detail are key to ensuring that rebar meets specifications.

Responsibilities of a Rebar Fabricator include preparing rebar for installation, ensuring it fits within the project's framework. They work closely with construction crews to deliver materials on time. This position requires physical strength and stamina, as well as a solid understanding of safety protocols. The Rebar Fabricator plays a crucial part in the construction process, providing the necessary support for building foundations and structures.

How to become a Rebar Fabricator?

Becoming a Rebar Fabricator involves a series of steps that require dedication and hard work. This role is essential in the construction industry, where precision and attention to detail are key. The following steps outline the path to becoming a skilled Rebar Fabricator.

First, it is important to understand the basics of rebar and its importance in construction. Rebar, short for reinforcing bar, strengthens concrete structures. Knowing how and why rebar is used sets the foundation for further learning and training. Next, acquiring formal education and training is crucial. Most employers prefer candidates with a high school diploma or equivalent. Some technical schools offer courses in construction or welding, which can be beneficial. After completing formal education, gaining experience through an apprenticeship is the next step. Working under an experienced Rebar Fabricator provides hands-on training and a deeper understanding of the job. Once enough experience is gained, obtaining relevant certifications can enhance job prospects. Certifications such as the Certified Reinforcing Steel Institute (CRSI) can add value to a resume. Finally, staying updated with the latest industry trends and technologies is important for career growth.

In summary, becoming a Rebar Fabricator involves understanding the role of rebar, completing formal education, gaining experience through an apprenticeship, obtaining certifications, and continuously learning. This structured approach ensures a solid foundation and a promising career in construction.

How long does it take to become a Rebar Fabricator?

Starting a career as a rebar fabricator involves a mix of education, training, and hands-on experience. Most people begin with a high school diploma or GED. Taking courses in math and blueprint reading helps. Some workers enter through vocational schools or apprenticeships. These programs can last from a few months to two years.

The total time to become a skilled rebar fabricator usually ranges from one to four years. During this period, workers gain essential skills through a combination of formal education and on-the-job training. This path ensures they understand safety rules, how to read construction plans, and how to use the right tools. Experienced fabricators often start as helpers, gaining valuable experience before moving up to more complex tasks. This journey not only builds practical skills but also opens up more opportunities in the construction industry.

Rebar Fabricator Job Description Sample

We are seeking a skilled Rebar Fabricator to join our construction team. The ideal candidate will be responsible for fabricating, cutting, bending, tying, and fixing reinforcement bars according to project specifications.

Responsibilities:

- Read and interpret blueprints and specifications to determine the layout of reinforcement bars.

- Cut, bend, tie, and fix reinforcement bars according to design specifications.

- Assemble and erect reinforcement bar assemblies for installation into concrete forms.

- Ensure that all reinforcement bars are properly positioned, aligned, and secured in accordance with the project requirements.

- Collaborate with other construction team members to ensure timely and efficient completion of projects.

Qualifications

- High school diploma or equivalent required; vocational training in welding or metal fabrication is a plus.

- Proven experience as a Rebar Fabricator or similar role in the construction industry.

- Strong knowledge of reinforcement bar fabrication techniques and construction terminology.

- Proficiency in using hand and power tools, as well as measuring and cutting equipment.

- Excellent attention to detail and ability to work with precision.

Is becoming a Rebar Fabricator a good career path?

A career as a Rebar Fabricator involves working in construction. These professionals prepare steel bars used in building projects. They cut, bend, and position the rebar according to design specifications. This job requires precision and physical strength. It often takes place in outdoor settings, which can be both challenging and rewarding.

Being a Rebar Fabricator offers several benefits. It provides stable employment with good pay. Many projects need skilled fabricators, so there is often work available. The job can lead to opportunities for advancement in construction management or supervision. However, it also has some challenges. The work can be physically demanding and may require long hours. Rebar Fabricators must work in various weather conditions, which can be tough.

Consider these pros and cons before pursuing this career:

- Pros:

- Stable job opportunities

- Good pay

- Potential for career advancement

- Cons:

- Physically demanding work

- Long hours

- Outdoor work in various weather

What is the job outlook for a Rebar Fabricator?

A career as a Rebar Fabricator offers a solid job outlook for professionals. The Bureau of Labor Statistics (BLS) highlights that approximately 1,900 job positions open each year. This consistent demand reflects the critical role that Rebar Fabricators play in the construction industry. Securing a position in this field can lead to long-term job stability and growth opportunities.

Job openings for Rebar Fabricators are expected to increase slightly. The BLS reports a projected growth rate of 1.2% from 2022 to 2032. This modest increase indicates a stable job market. Job seekers can anticipate steady opportunities as new projects and infrastructure developments continue to require skilled fabricators.

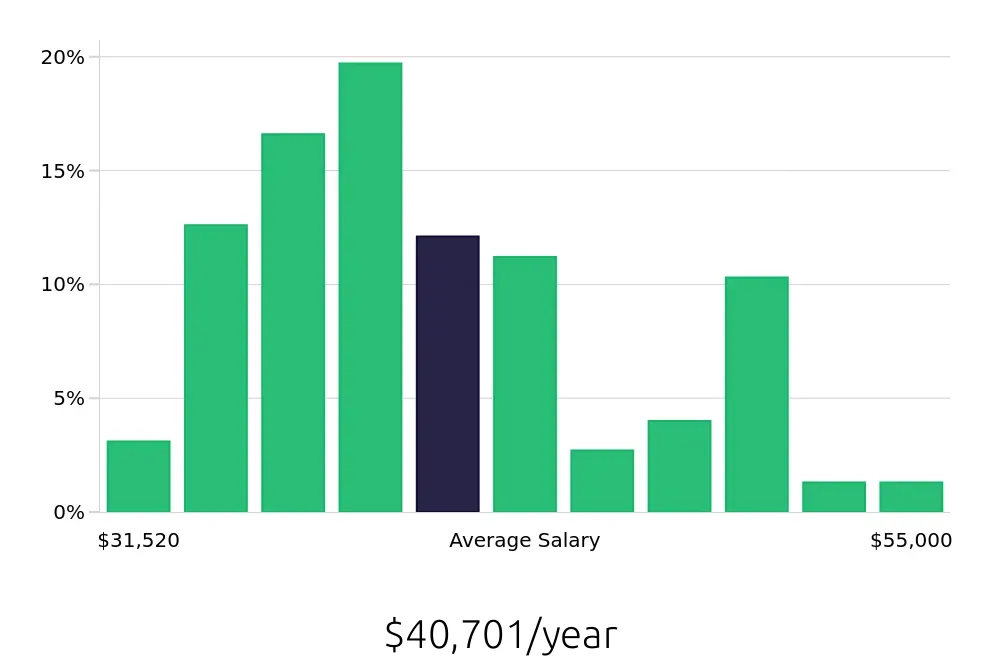

Compensation for Rebar Fabricators is competitive. The BLS reports an average national annual salary of $60,290. Additionally, the average hourly wage stands at $28.99. These figures reflect the value employers place on skilled professionals in this field. With experience and specialization, Rebar Fabricators can expect to earn even more, making this a financially rewarding career choice.

Currently 31 Rebar Fabricator job openings, nationwide.

Continue to Salaries for Rebar Fabricator