What does a Reliability Engineer do?

A Reliability Engineer plays a key role in ensuring that products and systems work properly and last longer. This professional focuses on identifying potential problems before they happen and finding ways to improve product durability. They work closely with design, manufacturing, and maintenance teams to develop strategies that reduce failures and extend the life of equipment. The goal is to keep the systems running smoothly, which helps the company save money and maintain a strong reputation.

The responsibilities of a Reliability Engineer include conducting thorough analyses of system failures, analyzing data to find patterns, and suggesting improvements. They create and implement plans to prevent future issues, such as regular maintenance schedules and testing protocols. They also develop reports and documentation to communicate findings and recommendations to other departments. Collaboration with cross-functional teams is crucial to ensure that reliability is integrated into all stages of product development. Reliability Engineers often use specialized tools and software to perform their duties effectively.

How to become a Reliability Engineer?

Becoming a Reliability Engineer can lead to a fulfilling career with many opportunities for growth. This professional focuses on ensuring equipment and systems run smoothly, reducing downtime, and extending the life of machinery. To start this career, one should follow a structured process.

First, obtaining the right education is essential. Most employers require at least a bachelor’s degree in engineering or a related field. It is beneficial to study areas like mechanical, electrical, or industrial engineering. This education provides the fundamental knowledge needed in this field. Second, gaining experience through internships or entry-level positions is crucial. This hands-on experience helps in understanding how theoretical knowledge applies in real-world scenarios. Third, obtaining certifications can enhance a candidate’s resume. Certifications from recognized bodies, such as the American Society of Mechanical Engineers (ASME), can make a candidate more attractive to potential employers. Fourth, developing strong problem-solving skills is important. This involves learning to analyze data and identify the root causes of equipment failures. Finally, staying current with industry trends and technologies helps in maintaining competitiveness and advancing in the field.

Following these steps can help one build a solid foundation in becoming a Reliability Engineer. Each step plays a vital role in preparing for a successful career in this specialized field.

- Earn a bachelor’s degree in engineering.

- Gain experience through internships or entry-level jobs.

- Obtain relevant certifications.

- Develop strong problem-solving skills.

- Stay updated with industry trends.

How long does it take to become a Reliability Engineer?

The journey to becoming a Reliability Engineer involves a mix of education, training, and experience. Generally, a bachelor's degree in engineering or a related field takes about four years. During this time, students learn key subjects like mechanics, thermodynamics, and materials science.

After earning a degree, new graduates might start as an intern or in a junior position. This hands-on experience helps them apply what they learned in school to real-world problems. Typically, gaining several years of practical experience, often around three to five, prepares someone to handle more complex tasks. In this time, professionals can specialize in areas such as mechanical reliability, process reliability, or maintenance strategy. The combination of formal education and on-the-job experience leads to a solid foundation in reliability engineering.

Reliability Engineer Job Description Sample

We are seeking a skilled Reliability Engineer to join our team. The ideal candidate will be responsible for identifying potential failure points in our systems and processes, and implementing strategies to improve reliability and performance.

Responsibilities:

- Conduct failure analysis and root cause analysis to identify the underlying causes of system and process failures.

- Develop and implement reliability improvement plans and strategies.

- Collaborate with cross-functional teams to design and implement reliability testing and validation processes.

- Analyze reliability data to identify trends and areas for improvement.

- Develop and maintain reliability metrics and reports.

Qualifications

- Bachelor's degree in Engineering, preferably in Mechanical, Electrical, or Industrial Engineering.

- Minimum of 3-5 years of experience in reliability engineering or a related field.

- Strong analytical and problem-solving skills.

- Excellent communication and interpersonal skills.

- Familiarity with reliability analysis tools and software.

Is becoming a Reliability Engineer a good career path?

A Reliability Engineer plays a key role in maintaining and improving the efficiency of machinery and systems. This career path focuses on ensuring equipment runs smoothly to prevent downtime and costly repairs. They analyze data, design maintenance schedules, and work with cross-functional teams to implement reliability programs. This role requires a mix of technical skills, problem-solving abilities, and teamwork.

Choosing to be a Reliability Engineer comes with its own set of advantages and challenges. For those interested in this field, understanding these can help make an informed decision. Here are some pros and cons to consider:

- Pros:

- Opportunities to work on cutting-edge technology.

- High demand for skilled professionals in various industries.

- Potential for career growth and advancement.

- Job stability with the increasing focus on efficiency and reliability.

- Cons:

- Potential for working long hours, especially during maintenance periods.

- Need to stay updated with the latest industry trends and technologies.

- Can involve working in challenging or hazardous environments.

- Requires strong analytical skills and problem-solving abilities.

Overall, a career as a Reliability Engineer offers a mix of technical challenges and rewarding outcomes. It is ideal for those who enjoy solving problems and ensuring operational efficiency.

What is the job outlook for a Reliability Engineer?

Job seekers interested in a career as a Reliability Engineer can look forward to a positive job outlook. According to the Bureau of Labor Statistics (BLS), the field has an average of 89,900 job positions available each year. This steady demand indicates a reliable career path for those who pursue it. With a projected growth of 8.5% from 2022 to 2032, it is clear that the industry is expanding.

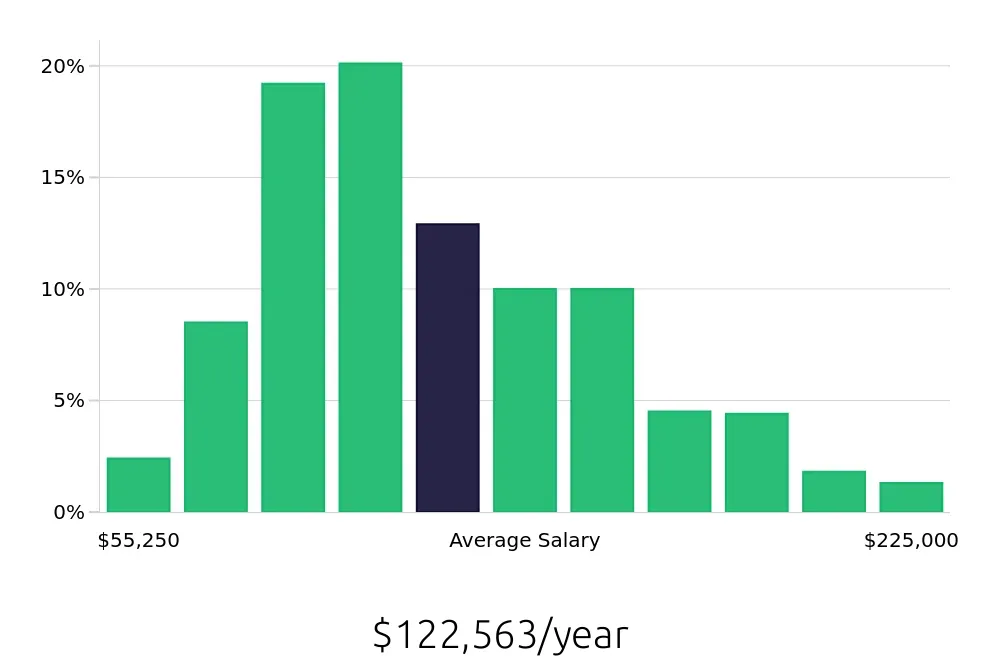

Reliability Engineers enjoy a competitive average national annual compensation of $100,980. This figure highlights the value placed on their skills and expertise. Hourly, they earn an average of $48.55, reflecting the importance of their role in maintaining operational efficiency. These figures show that the profession is not only stable but also financially rewarding.

The combination of consistent job openings and promising salary prospects makes Reliability Engineering an attractive career choice. Job seekers can look forward to a field that offers both growth and financial stability. For those considering this career path, the data from BLS suggests a bright future ahead.

Currently 273 Reliability Engineer job openings, nationwide.

Continue to Salaries for Reliability Engineer