What does a Sewing Machine Operator do?

A Sewing Machine Operator plays a key role in the manufacturing process. They use sewing machines to join pieces of fabric together. This creates garments, upholstery, and other textile products. Operators must follow precise instructions and patterns. They ensure the final product meets quality standards. This role requires attention to detail and steady hands.

The responsibilities of a Sewing Machine Operator include setting up the machine, threading the needle, and adjusting tension. They cut fabric according to specifications and operate the machine to sew pieces together. Operators also inspect finished products for defects. They may need to make adjustments to the machine or fabric to correct issues. This job often involves working with a team to meet production deadlines. It requires a good understanding of sewing techniques and tools.

How to become a Sewing Machine Operator?

Becoming a sewing machine operator can lead to a rewarding career in the manufacturing industry. This role involves using various types of sewing machines to create and repair garments and other textile products. The process to become a sewing machine operator is straightforward and can be completed in a few key steps.

First, gaining a basic understanding of sewing machines is essential. This includes learning how to set up and operate the machines, as well as understanding different types of stitches and fabrics. Next, formal training or education can be beneficial. Many community colleges and vocational schools offer courses in sewing and garment production. These courses provide hands-on experience and teach important skills. After completing a course, gaining practical experience is crucial. This can be done through internships, apprenticeships, or entry-level positions in a garment factory. Experience helps to refine skills and understand the industry better. Finally, obtaining certification can enhance job prospects. Organizations like the National Center for Construction Education & Research (NCCER) offer certification programs that validate skills and knowledge. Networking with industry professionals and staying updated on industry trends can also improve job opportunities.

To summarize, the journey to becoming a sewing machine operator involves:

- Learning about sewing machines

- Completing formal training or education

- Gaining practical experience

- Obtaining certification

- Networking and staying informed

How long does it take to become a Sewing Machine Operator?

The journey to becoming a sewing machine operator varies based on several factors. Most people can learn the basics in a few weeks. Training programs often last from one to six months. These programs teach essential skills like threading a machine, adjusting tension, and reading patterns. Some programs also cover more advanced techniques.

Experience plays a big role in mastering the job. Beginners may start with simple tasks. Over time, they gain the skills needed for more complex projects. Many operators continue to learn new techniques throughout their careers. This ongoing learning helps them stay competitive in the job market. With dedication and practice, anyone can become a skilled sewing machine operator.

Sewing Machine Operator Job Description Sample

A Sewing Machine Operator is responsible for operating and maintaining sewing machines to produce high-quality garments and textiles. This role requires precision and attention to detail to ensure that all products meet the required standards.

Responsibilities:

- Operate and maintain sewing machines to produce high-quality garments and textiles.

- Inspect materials and products for quality and accuracy.

- Follow production schedules and meet deadlines.

- Perform routine maintenance and troubleshooting of sewing machines.

- Collaborate with other team members to ensure smooth production flow.

Qualifications

- High school diploma or equivalent.

- Previous experience as a Sewing Machine Operator or similar role.

- Proficiency in operating various types of sewing machines.

- Attention to detail and precision.

- Ability to work in a fast-paced environment.

Is becoming a Sewing Machine Operator a good career path?

Working as a Sewing Machine Operator offers a blend of hands-on skills and repetitive tasks. This role involves using sewing machines to join fabric pieces, often in a factory setting. The job requires attention to detail and the ability to work efficiently. Operators often work with various materials, from textiles to leather. This career path can lead to opportunities in different industries, including apparel, furniture, and automotive.

The job has its pros and cons. On the positive side, it offers steady employment and the chance to work in a team environment. Operators can often find jobs with local companies, reducing commute times. The work is mostly repetitive, which can be comforting for those who prefer routine. However, the job can be physically demanding, requiring long periods of standing and repetitive motions. It may also offer limited opportunities for advancement without additional training or education. Understanding these factors can help job seekers decide if this career is right for them.

Consider these pros and cons before pursuing a career as a Sewing Machine Operator:

- Pros:

- Steady employment opportunities

- Teamwork and collaboration

- Potential for local job openings

- Cons:

- Physical demands and repetitive motions

- Limited advancement without additional training

What is the job outlook for a Sewing Machine Operator?

The job outlook for sewing machine operators shows a steady demand in the manufacturing industry. Each year, the Bureau of Labor Statistics (BLS) reports around 12,500 job positions available for sewing machine operators. This number highlights the ongoing need for skilled workers in this field. Despite a projected decrease of 15.2% in job openings from 2022 to 2032, the role remains vital in various sectors.

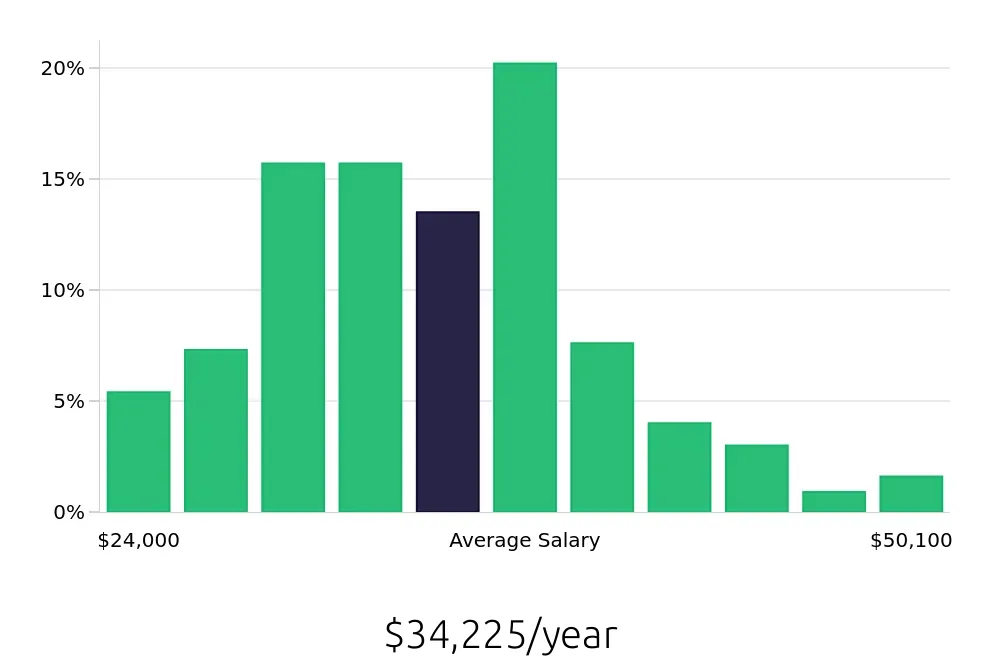

Sewing machine operators earn an average national annual compensation of $35,000, according to the BLS. This figure reflects the value of their skills and the importance of their work in the production process. The average national hourly compensation stands at $16.83, offering a competitive wage for those in the field. These figures make the role attractive for job seekers looking for stable and rewarding employment.

For those considering a career as a sewing machine operator, the job market offers both challenges and opportunities. While the number of job openings may decline, the demand for skilled operators will continue. This role provides a solid foundation for a career in manufacturing, with potential for growth and advancement. Job seekers should focus on developing their skills and staying updated with industry trends to thrive in this field.

Currently 84 Sewing Machine Operator job openings, nationwide.

Continue to Salaries for Sewing Machine Operator