What does a Sheet Metal Mechanic do?

A Sheet Metal Mechanic works with metal sheets to create and repair various products. They use tools to cut, bend, and shape metal into different forms. This job requires precision and attention to detail. Sheet Metal Mechanics often work with blueprints and technical drawings to understand what needs to be made. They may work in factories, construction sites, or workshops.

These professionals use different tools like saws, drills, and welders. They must follow safety rules to avoid injuries. Sheet Metal Mechanics often work as part of a team. They need to communicate well with others to ensure projects are completed correctly. This job can involve both manual labor and using machinery. It is a hands-on role that requires skill and experience. Sheet Metal Mechanics play a key role in many industries, from construction to manufacturing.

How to become a Sheet Metal Mechanic?

Becoming a Sheet Metal Mechanic involves a series of steps that lead to a rewarding career. This profession requires a mix of technical skills and hands-on experience. By following a structured path, individuals can successfully enter this field.

The journey to becoming a Sheet Metal Mechanic starts with education and training. Here are the key steps:

- Obtain a high school diploma or GED. This is the first step towards a career in this field.

- Complete a vocational or technical training program. These programs teach essential skills and knowledge.

- Gain experience through apprenticeships or entry-level positions. Practical experience is crucial in this trade.

- Obtain necessary certifications. Certifications can enhance job prospects and credibility.

- Continue education and stay updated with industry trends. Ongoing learning is important for career growth.

Each step builds on the previous one, leading to a successful career as a Sheet Metal Mechanic. By following this path, individuals can develop the skills needed to excel in this field.

How long does it take to become a Sheet Metal Mechanic?

The journey to becoming a Sheet Metal Mechanic involves several steps. First, a person needs to complete a formal training program. This often includes both classroom instruction and hands-on experience. Many programs last between two to four years. These programs teach essential skills like reading blueprints, working with metal, and using various tools.

After completing a training program, the next step is gaining practical experience. This can happen through an apprenticeship. Many apprentices work under experienced mechanics for several years. During this time, they learn more about the job and how to handle different tasks. Some mechanics choose to get certified. This can improve job opportunities and earning potential. Certification often requires passing an exam and meeting certain work experience requirements.

Sheet Metal Mechanic Job Description Sample

We are seeking a skilled Sheet Metal Mechanic to join our team. The ideal candidate will have a strong background in sheet metal fabrication, welding, and HVAC systems. This role involves working with various materials, including sheet metal, copper, and aluminum, to create and repair ductwork, vents, and other metal components.

Responsibilities:

- Read and interpret blueprints, technical drawings, and specifications to determine work requirements.

- Cut, bend, shape, and assemble sheet metal components using hand and power tools.

- Weld and braze metal parts to construct ductwork, exhausts, and other metal assemblies.

- Install, align, and secure sheet metal components using various tools and equipment.

- Perform routine maintenance and repairs on HVAC systems and sheet metal products.

Qualifications

- High school diploma or equivalent required; vocational training in sheet metal mechanics or a related field is preferred.

- Minimum of 2-3 years of experience in sheet metal fabrication and HVAC systems.

- Proficiency in using hand and power tools, including saws, drills, welders, and measuring tools.

- Strong understanding of blueprints, technical drawings, and safety regulations.

- Ability to work independently and as part of a team.

Is becoming a Sheet Metal Mechanic a good career path?

A Sheet Metal Mechanic works with metal to create and repair items. This job involves cutting, bending, and assembling metal sheets. They use tools to shape metal into parts for buildings, machines, and appliances. This job needs good hand-eye coordination and attention to detail. Sheet Metal Mechanics often work with other tradespeople, like electricians and plumbers, to ensure everything fits together well.

Working as a Sheet Metal Mechanic has its own set of advantages and challenges. Here are some pros and cons to consider. Good pay and job stability are key benefits. Skilled Sheet Metal Mechanics often earn a good salary and find steady work. This job offers the chance to work on a variety of projects, from small repairs to large construction jobs. It also provides opportunities to travel and work in different locations. However, the job can be physically demanding. It requires long hours on feet, lifting heavy materials, and working in uncomfortable positions. Safety is also a concern, as workers must follow strict safety rules to avoid injuries.

Here are some more details to think about:

- Pros:

- Good pay and job stability

- Variety of projects and travel opportunities

- Skill development and career advancement

- Cons:

- Physically demanding work

- Long hours and potential for fatigue

- Need to follow strict safety rules

What is the job outlook for a Sheet Metal Mechanic?

The job outlook for Sheet Metal Mechanics shows a steady demand in the industry. The Bureau of Labor Statistics (BLS) reports an average of 11,400 job positions available each year. This consistent number indicates a reliable career path for those entering the field. Job seekers can expect a stable environment with opportunities to grow and develop their skills.

Despite a slight projected decrease of 0.1% in job openings from 2022 to 2032, the field remains promising. This minor change suggests that while the number of positions may shrink, the demand for skilled professionals will still be present. Job seekers should focus on acquiring the necessary skills and certifications to remain competitive in the job market.

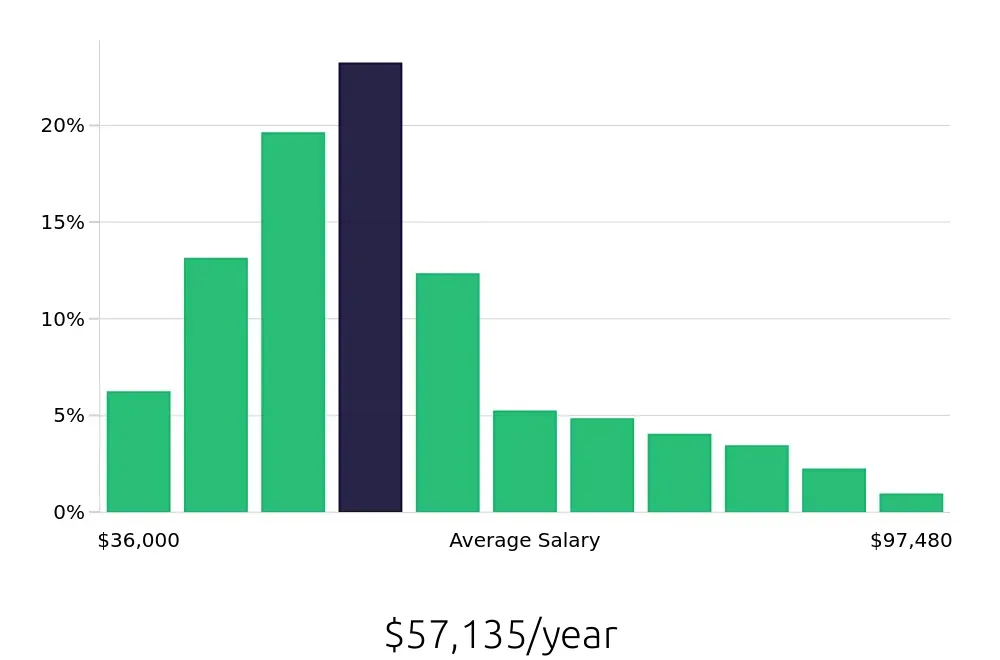

Sheet Metal Mechanics enjoy a competitive salary, with an average national annual compensation of $64,270. The hourly rate stands at $30.9, reflecting the value of their expertise. This attractive compensation package makes the career path appealing for those looking to balance job satisfaction with financial stability. Job seekers can look forward to a rewarding career with a strong earning potential.

Currently 192 Sheet Metal Mechanic job openings, nationwide.

Continue to Salaries for Sheet Metal Mechanic