What does a Tooling Engineer do?

A Tooling Engineer plays a key role in the manufacturing industry. They design and create tools that help produce high-quality products. Their work ensures that the production process runs smoothly and efficiently. Tooling Engineers work closely with production teams to understand their needs and challenges. They use their skills to solve problems and improve manufacturing processes.

The responsibilities of a Tooling Engineer include designing and modifying tools, managing project timelines, and collaborating with other engineers. They need to have a strong understanding of materials and manufacturing processes. Tooling Engineers also ensure that tools meet safety standards and regulations. Their work directly impacts the quality and speed of production. They are essential in keeping production lines productive and effective.

To succeed in this role, a Tooling Engineer needs strong technical skills and problem-solving abilities. Communication skills are also important, as they work with many different teams. Attention to detail ensures that tools function correctly. Tooling Engineers who excel in their job contribute to the success of the entire manufacturing process.

How to become a Tooling Engineer?

Becoming a Tooling Engineer can lead to a rewarding career. This profession involves designing and creating tools to manufacture products. Follow these steps to pursue this path:

- Get a relevant education: Start with a high school diploma. Consider taking courses in math, science, and technology. A college degree in mechanical engineering, industrial engineering, or a related field is helpful.

- Gain practical experience: Look for internships or entry-level jobs in manufacturing or engineering. This experience helps to understand the tools and processes used in the industry.

- Learn specialized skills: Familiarize yourself with CAD software, programming languages, and other tools used in tooling engineering. Online courses and workshops can be very useful.

- Work in the field: Apply for jobs that allow you to work as a Tooling Engineer. Start in an entry-level role and gain experience. Network with other professionals to learn more about the industry.

- Continue learning: The technology and methods in tooling engineering are always changing. Stay updated by taking advanced courses and attending conferences.

Each step builds upon the previous one, leading to a successful career as a Tooling Engineer. With dedication and the right education, one can master the skills needed for this important role.

How long does it take to become a Tooling Engineer?

The journey to becoming a Tooling Engineer combines education, training, and experience. Most start with a bachelor's degree in mechanical engineering or a related field. This often takes four years to complete. During this time, students learn about materials, design, and manufacturing processes.

After earning a degree, gaining practical experience is key. Some choose to work as engineering interns or in entry-level positions. These roles provide hands-on experience with tools and machinery. Experience helps new engineers understand real-world challenges and solutions. Many spend a few years in this phase, building skills and knowledge. Some may also choose to get certifications in specialized tools or software to stand out in the job market.

Tooling Engineer Job Description Sample

We are seeking an experienced Tooling Engineer to design, develop, and implement manufacturing tools and equipment. The Tooling Engineer will work closely with cross-functional teams to ensure that production tooling meets quality standards and production timelines.

Responsibilities:

- Design, develop, and implement manufacturing tools, fixtures, and equipment.

- Collaborate with cross-functional teams to understand production requirements and constraints.

- Conduct feasibility studies and cost analyses to ensure the efficiency and effectiveness of tooling solutions.

- Create and maintain detailed technical documentation, including blueprints, schematics, and operational manuals.

- Oversee the installation and setup of new tooling systems, ensuring proper alignment with production processes.

Qualifications

- Bachelor’s degree in Mechanical Engineering, Industrial Engineering, or a related field.

- Minimum of 5 years of experience in a tooling or manufacturing engineering role.

- Strong knowledge of CAD software and 3D modeling tools.

- Proficiency in using CNC machines and other advanced manufacturing equipment.

- Excellent problem-solving skills and attention to detail.

Is becoming a Tooling Engineer a good career path?

A Tooling Engineer plays a key role in manufacturing and production. They design and build the tools used to make products. This job combines creativity with technical skills. It ensures that tools and machinery work well and efficiently. The work often involves working with different teams. They need to understand both the engineering and the manufacturing sides.

Choosing this career path offers many opportunities. Tooling Engineers often enjoy a steady job market. They can find work in many industries. Companies always need skilled engineers. The work can be challenging and rewarding. Engineers get to see their designs in real products. They also have the chance to improve processes and save time. However, this job is not without its challenges. Engineers must stay updated on new technologies. They also need to work under tight deadlines. Long hours and stress are common. Engineers must balance their work and personal life well.

Consider these pros and cons before choosing this path:

- Pros:

- Stable job market.

- Opportunity to work in many industries.

- Chance to see your designs in real products.

- Opportunity to improve manufacturing processes.

- Cons:

- Need to stay updated on new technologies.

- Often work under tight deadlines.

- Long hours and stress are common.

- Must balance work and personal life well.

What is the job outlook for a Tooling Engineer?

The job outlook for Tooling Engineers is quite promising for those in the field. The Bureau of Labor Statistics (BLS) reports an average of 19,200 job positions each year. This steady demand makes it an attractive career path for job seekers. The BLS also projects a 10% increase in job openings from 2022 to 2032. This growth suggests a favorable career trajectory for those entering or considering a career in tooling engineering.

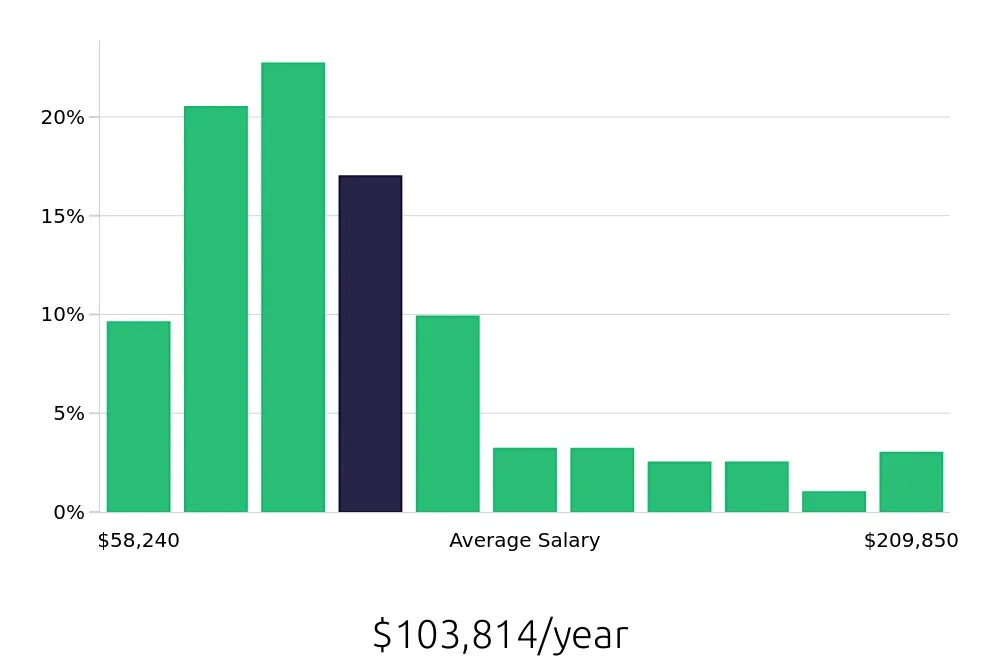

Tooling Engineers enjoy a competitive salary as well. According to the BLS, the average national annual compensation for this role stands at $105,220. This figure highlights the financial rewards of pursuing a career in this field. Additionally, the BLS reports an average national hourly compensation of $50.59. This pay reflects the skills and expertise that Tooling Engineers bring to their roles, making it a lucrative choice for many professionals.

For job seekers, this career path offers stability and growth. The combination of consistent job openings and a strong salary make it an appealing option. The positive job outlook and attractive compensation make Tooling Engineering a viable choice for those looking to build a successful career. Exploring opportunities in this field can lead to both professional fulfillment and financial stability.

Currently 65 Tooling Engineer job openings, nationwide.

Continue to Salaries for Tooling Engineer