What does a Welder/Fabricator do?

A welder/fabricator plays a crucial role in various industries, from construction to manufacturing. This professional uses specialized tools to join metal parts together. They create structures, machinery, and other products by welding metal sheets, pipes, and bars. The work requires precision and attention to detail to ensure the final product is strong and safe.

The welder/fabricator also interprets blueprints and technical drawings. They measure, cut, and bend metal to fit specific requirements. This role often involves working with different types of metals, including steel, aluminum, and stainless steel. Safety is a top priority, as welders/fabricators must wear protective gear to avoid burns and other injuries. This position demands both technical skills and a steady hand to produce high-quality work.

How to become a Welder/Fabricator?

Becoming a welder or fabricator offers a rewarding career path with steady demand. This profession involves joining materials, usually metals, using heat. It requires skill and precision. Here is a clear guide to help someone start this career.

First, gaining the right education is crucial. Many welders and fabricators start with a high school diploma. Some choose to attend a trade school or community college. These programs offer hands-on training and certifications. This education helps build the skills needed for the job. Next, obtaining certifications can boost job prospects. The American Welding Society (AWS) offers various certifications. These prove a welder's skills and knowledge. Certifications can lead to higher pay and better job opportunities.

After education and certification, gaining experience is important. Many start with an apprenticeship. This allows new welders to learn from experienced professionals. Apprenticeships provide practical training and often lead to full-time jobs. Some may also choose to work in entry-level positions. This helps build a resume and gain more experience. Networking with other professionals can also open doors. Joining welding associations or attending job fairs can help find job openings. Finally, staying updated with the latest technology and techniques is key. The welding industry is always evolving. Continuing education and training can keep skills sharp and competitive.

- Obtain a high school diploma or equivalent.

- Attend a trade school or community college for welding training.

- Get certified by the American Welding Society (AWS).

- Start with an apprenticeship or entry-level job.

- Continue education and stay updated with industry trends.

How long does it take to become a Welder/Fabricator?

The journey to becoming a skilled welder or fabricator involves several steps. First, individuals often complete a high school diploma or GED. This foundational education sets the stage for further training. Many then enroll in a trade school or vocational program. These programs typically last between one to two years. They focus on teaching essential welding techniques and safety practices.

During this time, students gain hands-on experience. They learn to use various tools and equipment. They also practice reading blueprints and interpreting technical drawings. Some programs offer internships or apprenticeships. These opportunities allow students to work under experienced professionals. They apply what they have learned in real-world settings. This practical experience is crucial for developing the skills needed in the industry.

Welder/Fabricator Job Description Sample

We are seeking a skilled Welder/Fabricator to join our team. The ideal candidate will have a strong background in welding and metal fabrication, with the ability to interpret blueprints and technical drawings.

Responsibilities:

- Perform welding and fabrication tasks according to blueprints and specifications.

- Cut, bend, and assemble metal components using various welding techniques.

- Inspect and test welds to ensure quality and adherence to safety standards.

- Maintain and repair welding equipment and tools.

- Collaborate with engineers and other team members to ensure project completion.

Qualifications

- High school diploma or equivalent required; technical training or degree in welding or metal fabrication preferred.

- Proven experience as a Welder/Fabricator.

- Proficiency in reading and interpreting blueprints and technical drawings.

- Strong knowledge of welding techniques and metal fabrication processes.

- Ability to work with precision and attention to detail.

Is becoming a Welder/Fabricator a good career path?

A career as a welder/fabricator offers a blend of hands-on work and technical skill. This role involves cutting, shaping, and joining materials, often metals, to create structures or parts. The job can take place in various settings, from construction sites to manufacturing plants. Welders and fabricators use tools like torches and welding machines. They must follow safety rules to protect themselves from heat and sparks.

Choosing this career path has its own set of advantages and challenges. On the positive side, welders and fabricators often enjoy steady employment. Many industries rely on these skilled workers. The job can also offer good pay, especially for those with specialized skills. However, the job can be physically demanding. Workers may spend long hours standing or in awkward positions. The work can also be dangerous, requiring careful attention to safety protocols. Despite these challenges, many find the work rewarding and fulfilling.

Here are some pros and cons to consider:

- Pros:

- Steady job opportunities

- Good pay potential

- Opportunities for skill development

- Cons:

- Physically demanding work

- Potential for injury

- Long hours and sometimes irregular schedules

What is the job outlook for a Welder/Fabricator?

The job outlook for welders and fabricators remains strong, with an average of 45,400 job positions available each year. This steady demand offers a promising career path for skilled professionals. The Bureau of Labor Statistics (BLS) projects a 0.7% increase in job openings from 2022 to 2032, indicating a stable and growing industry.

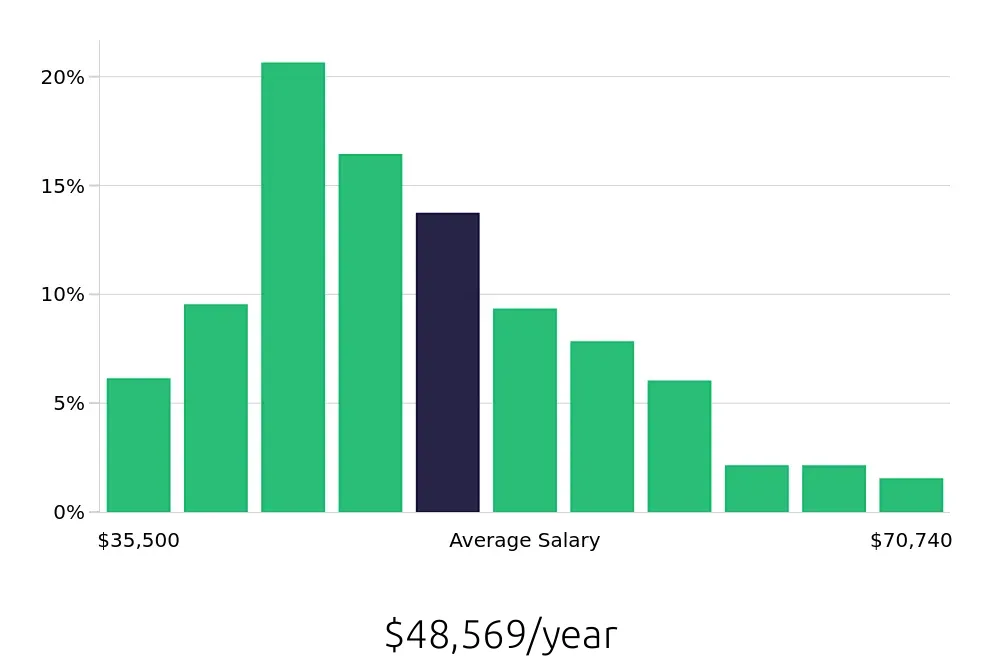

Welders and fabricators can expect a competitive salary, with an average national annual compensation of $52,240. This figure reflects the value of skilled labor in the field. Hourly compensation averages $25.12, providing a clear picture of the earning potential for those in this profession. These figures highlight the financial rewards that come with expertise in welding and fabrication.

For job seekers, the combination of steady job growth and attractive compensation makes the field of welding and fabrication an excellent choice. The industry's stability and the potential for good earnings make it a worthwhile career path to consider. With the right skills and training, professionals can look forward to a rewarding and secure future in this field.

Currently 483 Welder/Fabricator job openings, nationwide.

Continue to Salaries for Welder/Fabricator