What does a Converting Operator do?

A Converting Operator plays a crucial role in the production line. They oversee the conversion process of raw materials into finished products. Their work ensures that all products meet the required standards and specifications. Attention to detail is key to preventing errors and ensuring quality.

Responsibilities include operating machinery, monitoring production processes, and conducting regular inspections. They must follow safety protocols to protect themselves and others. Communication with team members is important to coordinate tasks and resolve any issues that arise. This role requires a strong understanding of production techniques and quality control measures. It also demands a commitment to maintaining a clean and organized workspace.

How to become a Converting Operator?

Becoming a Converting Operator can be a rewarding career choice for those interested in manufacturing and precision work. This role requires a blend of technical skills and attention to detail. A Converting Operator helps transform raw materials into finished products, playing a key part in the production process. Here is an outline of the steps to follow on this career path.

Starting as a Converting Operator involves several important steps. Following this guide ensures a smooth transition into this profession. Here are five key steps to consider:

- Education and Training: Begin with a high school diploma or equivalent. Some employers may prefer or require additional training, such as a certificate in manufacturing or a related field.

- Gain Experience: Look for entry-level positions in manufacturing or production. Working in roles like machine operator or production assistant offers valuable hands-on experience.

- Learn the Tools: Familiarize yourself with the equipment used in converting operations. This includes presses, cutters, laminators, and other specialized machinery. Training programs or on-the-job learning can help.

- Develop Skills: Focus on building key skills such as precision, attention to detail, and problem-solving. Understanding materials and production processes is also crucial.

- Seek Certification: Consider obtaining relevant certifications. This can enhance your resume and increase your job prospects. Certifications in specific machinery or safety training can be beneficial.

How long does it take to become a Converting Operator?

Interest in becoming a Converting Operator grows each year. This career involves operating machines that transform paper, film, or plastic into useful products. The time it takes to start this career can vary. Many operators start with on-the-job training. This often lasts a few weeks to a few months. Training teaches new workers how to use the machines and maintain safety standards.

Education and experience also play key roles. Some companies prefer candidates with a high school diploma or GED. Others might require a certificate from a technical school. This program usually takes one to two years. These programs teach both theoretical and practical skills. Graduates learn about machine operation, maintenance, and safety. They also gain hands-on experience. This combination of education and training helps new operators hit the ground running.

Converting Operator Job Description Sample

We are seeking a skilled Converting Operator to join our production team. The Converting Operator will be responsible for operating and maintaining converting machines to produce high-quality finished products. This role requires attention to detail, strong technical skills, and the ability to work in a fast-paced environment.

Responsibilities:

- Operate and monitor converting machines to ensure efficient production.

- Perform regular machine maintenance and troubleshooting to minimize downtime.

- Inspect and adjust machine settings to achieve desired product quality.

- Ensure compliance with safety and quality standards.

- Collaborate with the production team to meet production targets and deadlines.

Qualifications

- High school diploma or equivalent required; technical or vocational training preferred.

- Proven experience as a Converting Operator or similar role.

- Strong understanding of converting machinery and operations.

- Proficient in performing routine maintenance and troubleshooting.

- Ability to read and interpret technical documents and blueprints.

Is becoming a Converting Operator a good career path?

A Converting Operator plays a vital role in the manufacturing process, focusing on transforming raw materials into finished products. This role demands a keen eye for detail and a solid understanding of machinery and production techniques. Operators ensure that each step in the conversion process runs smoothly, from loading materials to running machines and quality checking. Being proficient in using and maintaining specialized equipment is key to this career. Companies often look for candidates with a strong work ethic and the ability to work well in a team environment.

Working as a Converting Operator offers both rewarding and challenging aspects. One key benefit is the opportunity to develop technical skills that are in high demand in various industries. The job provides a stable career path with potential for growth into supervisory or managerial roles. However, it also comes with its set of challenges. Operators often work in physically demanding environments, which can be tiring. The job can also be repetitive, requiring operators to maintain high levels of concentration over long periods. Those considering this career path should weigh these factors to decide if it aligns with their career goals and lifestyle.

Here are some pros and cons to consider:

- Pros:

- Opportunity to develop valuable technical skills

- Potential for career advancement

- Work in a variety of industries

- Cons:

- Physically demanding work environment

- Jobs can be repetitive and require sustained attention

- May involve working irregular hours, including nights and weekends

What is the job outlook for a Converting Operator?

The job outlook for Converting Operators presents a promising yet cautious opportunity for job seekers. According to the Bureau of Labor Statistics (BLS), there are about 6,100 average job positions per year. This figure indicates a steady demand in the field, suggesting that opportunities will continue to be available. However, it is essential to note that there is a projected percent change in job openings of -7.2% from 2022 to 2032, which underscores the importance of staying informed about industry trends and adapting skills accordingly to secure employment in this role.

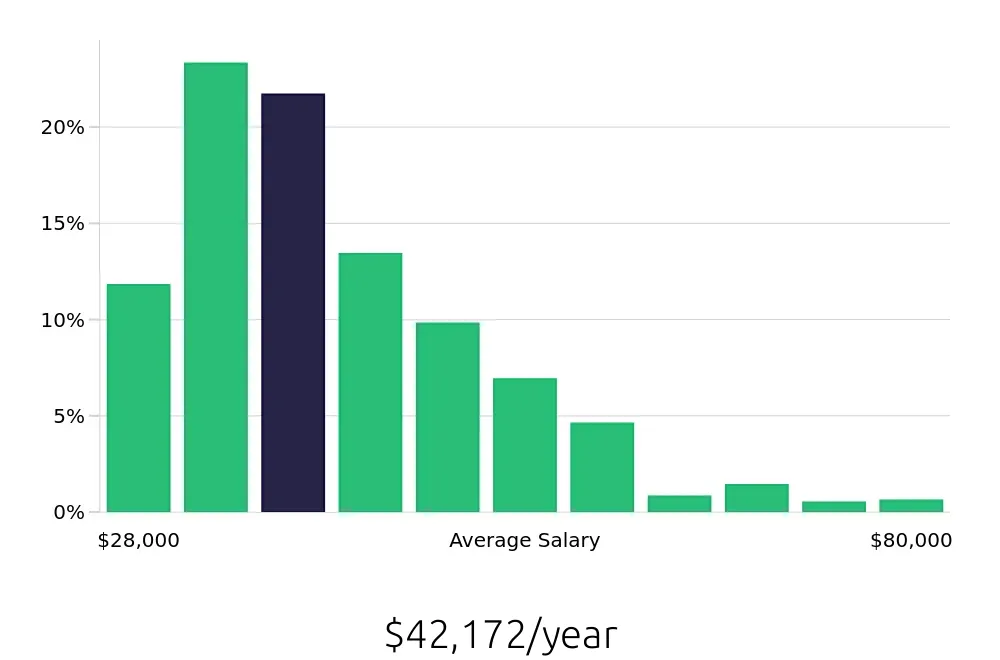

Prospective Converting Operators can expect a competitive salary that reflects the skills and responsibilities associated with the job. The average national annual compensation stands at $44,050, providing a solid financial foundation. Additionally, the average national hourly compensation is $21.18, offering clarity on what hourly earnings might look like. These figures can be beneficial when considering the financial aspect of this career path, as they provide a benchmark for what one might earn in this role. Staying updated with BLS data will help job seekers negotiate better and understand the market value of their expertise.

Considering these insights, job seekers interested in becoming Converting Operators should approach this career with a mix of optimism and strategic planning. The job market shows consistent opportunities, but a slight decrease in job openings suggests the need for proactive career management. By staying informed about industry changes and continuously upgrading skills, job seekers can navigate this career path successfully.

Currently 119 Converting Operator job openings, nationwide.

Continue to Salaries for Converting Operator