What does a Grain Elevator Operator do?

A Grain Elevator Operator oversees the safe and efficient handling of grain. This role involves managing grain from the time it arrives at the elevator until it is loaded for transport. Daily tasks include inspecting grain quality, controlling machinery, and ensuring all equipment operates smoothly. The operator also records data such as grain volume and quality, and maintains cleanliness standards.

Grain Elevator Operators coordinate with other staff to ensure the safe movement of grain. They communicate with suppliers and customers, keeping them informed of the status of their grain. The job requires attention to detail to prevent spills or contamination. Additionally, operators handle emergency situations and ensure all safety protocols are followed. This position plays a key role in the grain supply chain, contributing to its smooth operation.

How to become a Grain Elevator Operator?

Becoming a Grain Elevator Operator involves several important steps. This career path offers a stable and rewarding opportunity for those interested in agriculture and logistics. The job requires a blend of technical skills, safety awareness, and operational knowledge.

Below are the steps to start and advance in this profession.

- Obtain a high school diploma or equivalent: Most employers require at least a high school diploma. It provides a foundation for the technical knowledge needed later on.

- Complete on-the-job training: Many grain elevator operators start as trainees. Employers often provide this training. It covers safety procedures, equipment operation, and grain handling.

- Gain experience: Work under experienced operators to learn the job fully. Experience is critical. It helps understand the daily tasks and challenges of the job.

- Obtain necessary certifications: Some states require operators to get certified. These certifications ensure the operator understands local regulations and safety standards.

- Advancement opportunities: With experience, operators can advance to supervisory roles. Continuing education and advanced certifications can lead to higher-paying positions.

Following these steps can lead to a successful career as a Grain Elevator Operator. It's a path that combines practical skills with ongoing learning and development. Operators play a key role in the agriculture industry, ensuring grains are stored and transported efficiently.

How long does it take to become a Grain Elevator Operator?

The path to becoming a Grain Elevator Operator often starts with basic education and training. Many operators begin with a high school diploma or GED. Some take additional courses in agricultural sciences. Training can include on-the-job experience or formal programs at technical schools. These programs teach key skills and safety practices.

The time it takes to become a qualified operator can vary. Some people finish training in a few months. Others may take a year or more. This depends on the type of training and experience gained. On-the-job training can be shorter, but it needs commitment. Formal programs often provide a more structured path, leading to quicker qualifications. Building experience is crucial, so many operators start in entry-level positions and move up.

Grain Elevator Operator Job Description Sample

Grain Elevator Operators are responsible for managing the loading, unloading, and storage of grain at grain elevator facilities. They ensure efficient operations and adherence to safety and quality standards.

Responsibilities:

- Operate grain elevators and associated equipment to load, unload, and store grain.

- Monitor grain quality and storage conditions to maintain optimal grain condition.

- Coordinate with loading and unloading activities, including the use of scales and other measuring equipment.

- Inspect grain for quality and cleanliness, and report any issues to management.

- Ensure the safe operation of all equipment and adherence to safety protocols.

Qualifications

- High school diploma or equivalent required; additional education in agriculture or related field is a plus.

- Previous experience in grain handling or elevator operations preferred.

- Strong understanding of grain handling practices and quality standards.

- Ability to read and interpret technical documents and equipment manuals.

- Proficient in the use of scales, measuring equipment, and other grain handling tools.

Is becoming a Grain Elevator Operator a good career path?

Operating a grain elevator presents an exciting career path for those interested in agriculture and logistics. These operators manage the storage and movement of grains such as wheat, corn, and soybeans. Their tasks include overseeing the grain receiving process, ensuring quality control, and preparing grain for shipping. Working with modern equipment allows for efficiency and precision in the process.

Grain elevator operators must be detail-oriented and knowledgeable about grain handling. This role offers the opportunity to work in both rural and urban areas. Those in rural locations often have a closer connection to farming communities, while urban positions may involve more complex logistics operations.

Consider the following pros and cons before pursuing a career as a grain elevator operator:

- Pros:

- Job stability: The agriculture sector provides consistent employment opportunities.

- Skill development: Operators gain experience in machinery and logistics.

- Competitive pay: This role often comes with good wages and benefits.

- Cons:

- Physical demands: The job can be physically demanding and may require long hours.

- Weather dependency: Outdoor work is subject to weather conditions.

- Safety concerns: Operators must follow strict safety protocols to avoid accidents.

What is the job outlook for a Grain Elevator Operator?

The job outlook for Grain Elevator Operators looks promising, with an average of 3,300 positions opening each year. According to the Bureau of Labor Statistics (BLS), this field is expected to grow by 5.8% from 2022 to 2032. This growth provides a stable environment for job seekers interested in this role.

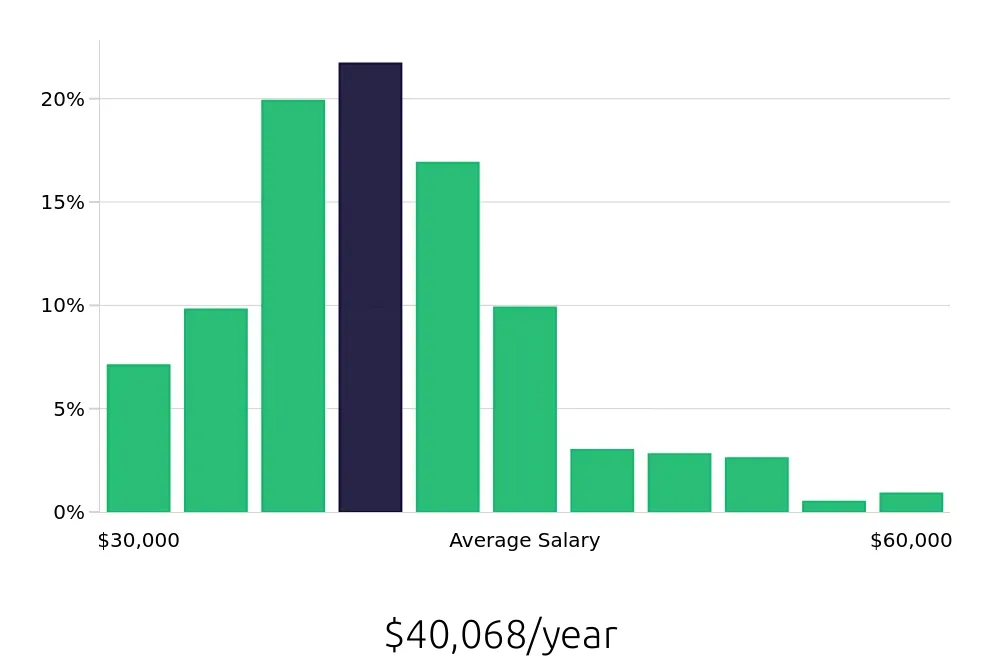

Grain Elevator Operators earn a competitive average annual salary of $42,900, as reported by the BLS. The hourly wage stands at approximately $20.63, making it a viable career choice for those seeking steady employment. This compensation reflects the importance of the role in the agricultural sector.

Job seekers entering the field can expect a stable job market with consistent demand. The combination of steady employment opportunities, competitive wages, and positive growth projections makes Grain Elevator Operator a worthwhile career path for those with the necessary skills and qualifications.

Currently 78 Grain Elevator Operator job openings, nationwide.

Continue to Salaries for Grain Elevator Operator