What does a Maintenance Planner do?

A Maintenance Planner schedules and coordinates maintenance tasks to ensure equipment and facilities run smoothly. This role involves preparing maintenance schedules, coordinating with maintenance teams, and ensuring all work complies with safety regulations. The Maintenance Planner assesses equipment needs and develops plans to address any potential issues. They work closely with other departments to prioritize maintenance tasks and minimize disruptions.

Responsibilities of a Maintenance Planner include analyzing equipment performance data, creating maintenance schedules, and tracking maintenance activities. They must communicate effectively with team members and other departments, ensuring everyone understands the maintenance plans. The Maintenance Planner also reviews work orders, estimates time and resources required, and ensures all maintenance tasks are completed efficiently. By doing this, they help maintain high operational standards and reduce downtime.

How to become a Maintenance Planner?

A Maintenance Planner plays a crucial role in ensuring the smooth operation of a facility's equipment. This professional is responsible for scheduling and coordinating maintenance activities to minimize downtime and keep operations running efficiently. Becoming a Maintenance Planner involves several steps.

First, one must obtain a high school diploma or equivalent. Building a strong foundation in math and science is beneficial. Next, gaining experience in maintenance or a related field helps. This could come from vocational training or on-the-job experience. Additionally, obtaining relevant certifications can boost job prospects. Courses in maintenance management or industrial technology are valuable. Building a strong network within the industry also provides valuable connections and opportunities. Finally, staying current with industry trends and technologies ensures long-term success.

To summarize, becoming a Maintenance Planner requires:

- Completing a high school education

- Gaining maintenance experience

- Obtaining relevant certifications

- Building a professional network

- Staying updated on industry trends

How long does it take to become a Maintenance Planner?

Getting a role as a Maintenance Planner involves a combination of education, training, and experience. This journey can vary widely based on your background and the specific requirements of your industry. Most commonly, it takes between two to four years to gain the necessary skills and experience.

First, many Maintenance Planners start with a high school diploma or equivalent. Some pursue further education, like an associate’s degree in industrial technology or a related field. This can take about two years. Next, on-the-job training and internships can provide valuable hands-on experience. This often adds another one to two years. For those with prior experience in maintenance or related roles, the transition to a Maintenance Planner can take less time, sometimes as little as a year if they already understand the core responsibilities and have relevant skills.

To speed up this process, consider enrolling in specialized training programs. These programs can cover important topics such as scheduling, inventory management, and safety protocols. Employers often value candidates who have completed such training. Additionally, gaining certifications can enhance your resume and open more opportunities.

In summary, becoming a Maintenance Planner is a rewarding path that requires dedication and the right combination of education, training, and experience. With commitment, you can enter this field and build a successful career.

Maintenance Planner Job Description Sample

The Maintenance Planner is responsible for planning, coordinating, and optimizing all maintenance activities to ensure minimal disruption to production schedules. This role involves working closely with the production team, maintenance staff, and management to schedule and execute maintenance tasks effectively.

Responsibilities:

- Develop and implement maintenance schedules to ensure all equipment is maintained according to planned maintenance systems.

- Coordinate with the production team to schedule maintenance during periods of low production activity to avoid disruptions.

- Analyze equipment downtime and maintenance history to improve maintenance strategies and reduce future downtime.

- Ensure compliance with all safety and regulatory standards in all maintenance activities.

- Maintain accurate records of all maintenance activities, parts used, and costs associated with maintenance.

Qualifications

- Bachelor’s degree in Engineering, Operations Management, or a related field.

- Proven experience as a Maintenance Planner or similar role.

- Strong understanding of maintenance planning principles, techniques, and tools.

- Excellent analytical and problem-solving skills.

- Proficient in using maintenance management software and Microsoft Office suite.

Is becoming a Maintenance Planner a good career path?

A Maintenance Planner plays a crucial role in keeping facilities running smoothly. This job focuses on organizing and overseeing maintenance activities. It involves creating schedules, ensuring resources are available, and minimizing downtime. Employers often look for candidates who can balance technical knowledge with strong organizational skills. Attention to detail and problem-solving abilities are key traits for success in this role.

The path to becoming a Maintenance Planner usually starts with a relevant degree or certification in fields like industrial maintenance or engineering technology. Many professionals begin their careers in entry-level positions, such as maintenance technicians, before advancing. Experience in related areas, like project management or logistics, can also be beneficial. Continuous learning and staying updated with industry trends are important for career growth.

Working as a Maintenance Planner has its benefits and challenges. Here are some pros and cons to consider:

- Pros:

- Opportunities to improve and maintain equipment.

- Steady demand in various industries, including manufacturing and construction.

- Potential for career advancement to higher managerial positions.

- Cons:

- May require working on weekends or during emergencies.

- Exposure to physical hazards and the need for protective gear.

- Need to manage strict deadlines and tight schedules.

What is the job outlook for a Maintenance Planner?

The job outlook for Maintenance Planners is promising for those in the job market. The U.S. Bureau of Labor Statistics (BLS) reports about 15,300 average job positions available each year. This stable demand makes it a good career path for many job seekers. With a growth rate of 1.6% from 2022 to 2032, this field shows steady growth. This means more opportunities are likely in the coming years.

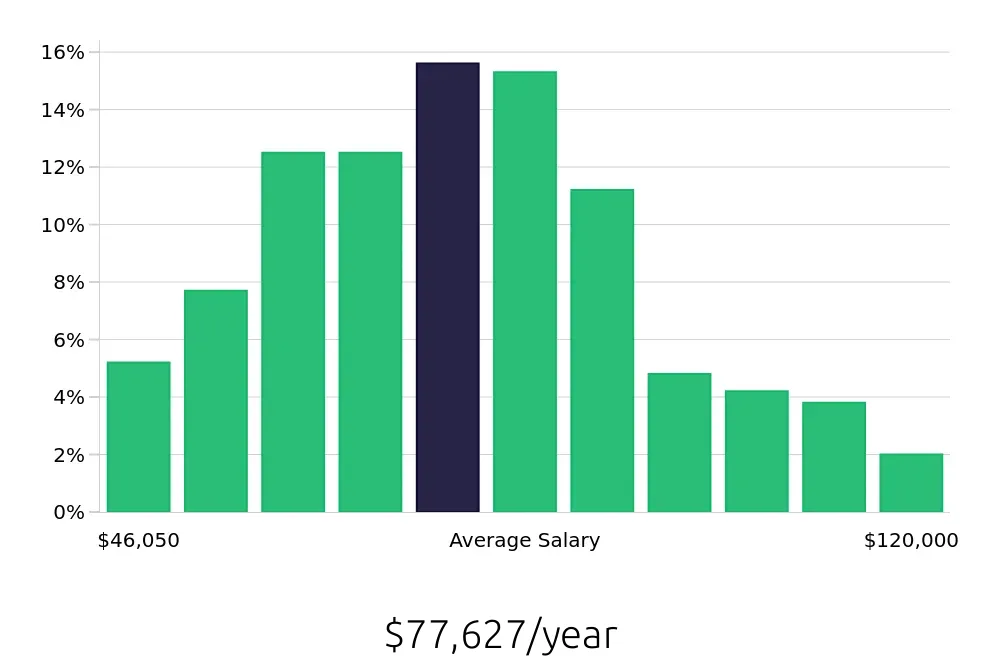

Maintenance Planners can expect a competitive salary as well. The BLS data shows an average national annual compensation of $125,900. This figure highlights the value companies place on skilled Maintenance Planners. In addition, the hourly compensation rate is $60.53. This pay reflects the specialized skills and knowledge needed for the job. With the right qualifications, job seekers can find good financial rewards in this career.

A career as a Maintenance Planner offers stability and growth. The combination of a steady number of job openings and a modest growth rate makes it an attractive option. Coupled with a strong average salary, this field provides both job security and the potential for financial success. Job seekers looking for a reliable career path will find much to like in this occupation.

Currently 213 Maintenance Planner job openings, nationwide.

Continue to Salaries for Maintenance Planner